Tips to get more mileage out of trailer technologies

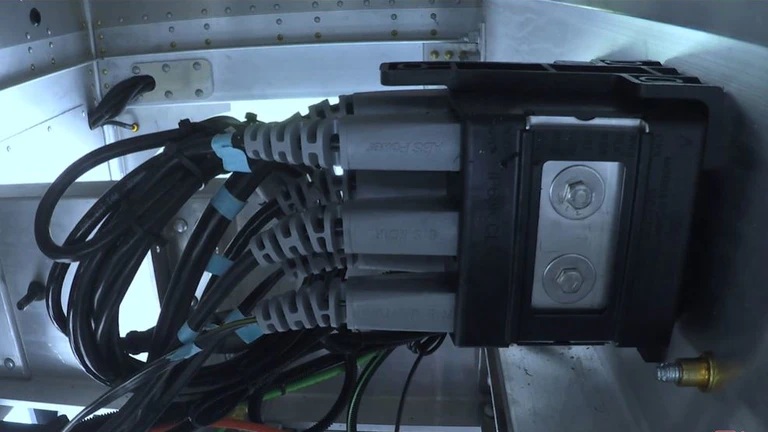

Diligent maintenance practices help fleets reap the benefits of cutting-edge sensors and lighting systems. A lot of emphasis has been placed on making trailers smarter, safer, and more resilient in…

Read more...

Last Comments