Diligent maintenance practices help fleets reap the benefits of cutting-edge sensors and lighting systems.

A lot of emphasis has been placed on making trailers smarter, safer, and more resilient in recent years. From telematics sensors and advanced lighting systems to innovative designs and construction materials, the trailer is becoming a high-value asset for a fleet.

Maintaining that value is also taking on a new level of importance. It’s important for fleets to have the proper inspection and preventive maintenance systems in place to make sure these new “bells and whistles” continue to function as the manufacturers intended.

Advanced lighting and wiring harnesses

When it comes to trailer lighting systems, water and corrosive materials are common culprits of system failure. Technicians must take proper care to guard against intrusions into the system. The proper use of dielectric grease in plugs and pins is an important step.

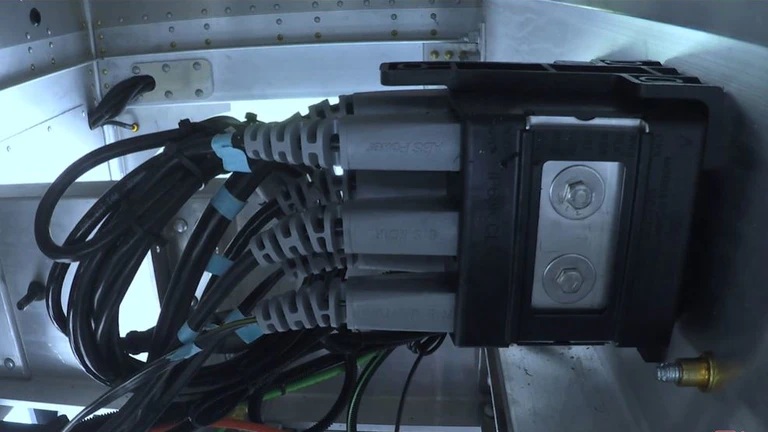

Products like Peterson Mfg.’s Defender Harness and Lighting System are designed to protect electrical systems from corrosive materials like road salt. This modular system consists of four components: The Defender distribution module, the nose box, a variety of modular harness components that connect to the Defender module, and Peterson LumenX LED lights.

“The special characteristics of these components make servicing trailers equipped with Defender unlike any other harness system,” says Jeff Geoffroy, director of marketing at Peterson Mfg., which provides a broad line of vehicle safety lighting, reflectors, antennas, mirrors, and related products.

While there is no requirement to perform scheduled preventive maintenance on the Defender system, different circumstances may warrant that certain maintenance steps be taken.

“Never disassemble the modular harness plugs from the distribution module unless diagnosis or repair is needed,” Geoffroy says. “If it becomes necessary to remove the clamp on the module, the technician must perform complete maintenance on all three connections on that side of the module.”

First, prior to disassembly, use compressed air to remove as much debris as possible from around the plug heads. Once cleaned, remove the plugs by pulling straight out, and then remove the silicone seals. Thoroughly clean all open module ports. Thoroughly inspect each plug and port, looking for signs of damage or corrosion. “If corrosion is found, it will be necessary to remove and replace the distribution module and all affected harness components,” Geoffroy says. “Remove any debris or contaminants from the face of the remaining Defender plugs.”

Once the inspection and any necessary repairs have been completed, it is vital to install new silicone seals. Add dielectric grease to the pin terminals. “Keep in mind that there are two types of clamps,” Geoffroy points out. “If the old-style clamp was removed, reassemble using the new-style splash reflecting clamp cover. Use only stainless steel bolts with thread-locking nylon patches.”

When replacing the distribution module, bolts and seals will be provided with a new module. It is imperative that the clamp bolts be torqued to 60 inch-pounds. “Over-torquing the clamp bolts will damage the distribution module and require its replacement,” Geoffroy warns.

One other issue a technician could run into is a poor connection at the SAE J560 receptacle, which transfers electrical power from the tractor to the trailer. That is typically due to the plug deforming and not fully locking into place, which promotes wear and deterioration. “The Defender receptacle is now 3/8-inches deeper, which helps cut down on rocking and helps lock it into place more positively,” Geoffroy points out. Thus, there is no reason to open the nose box unless system diagnostics require it.

“In the event that disassembly is needed, carefully remove the mounting bolts’ nuts,” Geoffroy says. “Do not attempt to force frozen fasteners loose. This could strip the carriage mounting threads. If a nut seizes, use a nut splitter to remove it.”

Whenever opening the nose box, Geoffroy says it’s a wise idea to add dielectric grease to the ring terminals and the enclosed female terminals for the J560 receptacle. Also, recognize that the nose box may be equipped with a gasket made of felt or rubber. “If the old-style felt gasket is present, replace it with a new reusable rubber gasket,” Geoffroy says. “If the J560 receptacle itself is damaged and requires replacement, it can be replaced without further disassembly. Just be sure to use a Peterson replacement receptacle.”

When closing the nose box back up, the connector retaining nuts and nuts around the perimeter must be torqued to 80 inch-pounds. “Applying excess torque may result in irreparable damage to the nose box components,” Geoffroy says.

Much like the Defender modular wiring harness, Geoffroy says the LumenX lights themselves require no scheduled preventive maintenance. On that note, connections should never be disconnected unless repair or replacement is needed.

“When working with LumenX lights, do not grease the silicone sealed connectors,” Geoffroy says. “Greasing the terminals will prevent the silicone seal from seating properly, which will lead to undo corrosion. On the other hand, you should apply dielectric grease to the .180 bullet connectors anytime they are disconnected and replaced.”

Sensors and telematics

Interior trailer maintenance, which includes lighting systems, can be aided by the use of a trailer telematics system. Various sensors strategically positioned throughout a trailer can help fleets gain real-time access to information that helps them adopt a more proactive approach.

One example is the Road Ready advanced trailer telematics system from Clarience Technologies. Road Ready is an agnostic solution that communicates with other sensors that are already onboard a trailer, such as ABS and TPMS, regardless of brand. Additionally, Road Ready offers its own suite of sensory devices to monitor things like interior cargo volumetrics, trailer temperature, door open/close events, and lighting outages.

“Lighting is one of the top CSA issues for tractor-trailers,” says Paul Sniegocki, chief technology officer at Clarience Technologies. “Our trailer telematics system can detect electrical issues throughout the trailer’s circuit. Fleets can even check the overall health of a lighting system remotely if they desire. If the sensor reports back that everything is okay, the fleet knows the electrical system is healthy. If everything isn’t okay, the fleet knows it has a maintenance issue to address — and now they can address it in a more proactive way.”

Road Ready sensors can be hardwired into a trailer’s electrical system. Fleets can also opt for a replaceable battery option. In either case, Sniegocki says installation is easy. The sensors are installed using a proven, industrial-strength VHB tape — the same kind of tape used to secure automotive bumpers.

The communication between the sensors and the Road Ready MCU (master control unit) is executed using wireless technology, which can provide advantages from a maintenance standpoint.

“When you think about the many systems on a commercial vehicle, a lot of maintenance issues tie back to connections,” Sniegocki points out. “With wireless sensors, you don’t have to worry about those potentially troublesome connections.”

Road Ready wireless sensors operate on replaceable batteries. Depending on how often a given sensor is asked to gather and report information, a given battery often lasts up to three years. Regardless, a fleet gets a notification when a battery is beginning to fail.

Aside from the sensors, the other key components of the Road Ready system are the MCU (aka the “brains” of the Road Ready system) and a SmartBridge Integrator (SBI). The SBI allows the Road Ready system to take information from partner sensory devices regardless of communication protocol, i.e. CAN bus, and transmit it to the MCU.

According to Sniegocki, both the Road Ready MCU and SBI are maintenance-free and built to withstand rigorous conditions. Installation is also straightforward.

“Using that same high-strength tape used to install the sensors, an MCU only takes about 15 minutes to mount on top of or at the front of a trailer,” Sniegocki says. “The SBI is easily installed in the rear of the trailer. It is completely sealed and uses automotive-grade sealed connections.”

PetersonPULSE is another trailer telematics solution that has come about over the past few years. This hardwired system is engineered to CAN bus specifications using cabling that is lighter, more flexible, and more installation-friendly than traditional harness cabling. Additionally, a backup battery provides power when the trailer is untethered.

In tandem with technologies from its partners, PULSE detects real-time status of numerous vital trailer systems such as ABS and TPMS. With respect to trailer interiors, PULSE monitors cargo temperature, cargo door status, and interior lighting.

“PetersonPULSE can be retrofitted onto existing trailers or installed at the factory by an OEM,” says Cory Adams, vice president of engineering at Peterson Mfg. Aside from normal electrical system maintenance, PULSE is relatively maintenance-free. When a technician does want to interface with the system, they can do so via a Bluetooth-capable handheld device. “An app allows interfacing and interaction with the trailer to diagnose issues or update software, for instance,” Adams points out.

Source: https://www.fleetmaintenance.com

CUT COTS OF THE FLEET WITH OUR AUDIT PROGRAM

The audit is a key tool to know the overall status and provide the analysis, the assessment, the advice, the suggestions and the actions to take in order to cut costs and increase the efficiency and efficacy of the fleet. We propose the following fleet management audit.