Hybrid technologies could be the biggest transition that the automotive industry will leap into to reach cleaner emission standards

In striving to become smarter, greener and cleaner, the automotive industry has invested substantial amount of R&D work towards making existing internal combustion (IC) engines more efficient. Lately, a lot of focus has also been devoted to electrification of the powertrain, either partially or completely. Given the stringent worldwide environmental targets, it is but pertinent to shift to pure electromobility or electrification of the powertrain in some manner. Hybridisation, in fact, is expected to witness extensive adoption across passenger and commercial vehicle segments in the near future.

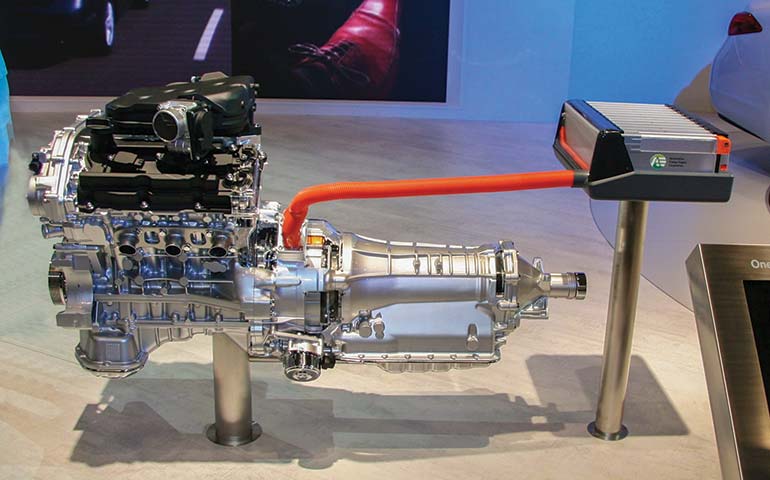

Hybridisation of the powertrain includes the addition of electric motor(s) to a vehicle, which is powered by an IC engine by default. While the motors are electric, the power source could vary between lithium-ion batteries to hydrogen fuel cells. When powered by a battery, the vehicle could either be a hybrid (HEV), whose motor is charged by the IC engine, or a plug-in hybrid (PHEV) that can be charged from an external source. In recent times, there have also been developments where traditional starter and generator components are experiencing changes that can be accommodated in hybrids as well as pure electric vehicles (EV).

HYBRID POWER SOURCE

Hybrids vary in their intensity of contributing to the power delivery of a vehicle, with categories such as mild to strong hybrid systems. In their most mild form, hybrid systems typically generate power, while a vehicle is braking and transfer this to the battery or generator. As the intensity grows, hybrid systems combine conventional powertrain components with electric components like motor, power electronics and high-voltage energy storage.

The range of product offerings that employ hybridisation ranges from passenger cars to buses, trucks and off-highway vehicles, including farm and construction equipment. The benefits of a hybrid system in a vehicle are plenty, with extended travel range and emergency power supply being top of the list. In many hybrid systems, the driver is provided with the option of switching between the IC engine and the electric motors, with the two working together when higher levels of power delivery are required.

Mild hybrids, combined with highly-optimised IC engines (mostly petrol), make a great value proposition for end-customers as well as vehicle manufacturers, since these technologies are comparatively affordable than pure electric or strong hybrid systems. Engines equipped with mild hybrid technologies do not have many additional components to an IC engine, and tend to offer relatively higher levels of efficiency to the vehicle. This may lead to mild hybrids emerging as the most preferred alternative powertrain technology choice for the automotive industry.

Another form of hybridisation that is also gaining good momentum globally is PHEVs. These systems require the addition of numerous components to support the vehicle’s electric motors as well as to manage the battery. PHEVs are claimed to provide customers the ‘best of both worlds’ of IC engines and electrification, since the vehicle basically has two independent power sources that can also work together, when needed. However, this system is pricey due to the existence of two powertrain systems as well as the addition of a number of components.

HYBRID TRANSMISSIONS

Since a hybrid vehicle combines an IC engine with one or more electric motors to power it, the method of delivering all that power to the wheels becomes important. This has led to top transmission suppliers like ZF offering plug-in hybrid transmissions to the market. The hybrid transmission carries out all functions of the standard transmission, along with advantages of the electric drive unit. It also has features like a separating clutch with low drag loss, which decouples the electric drive from the combustion engine and, in turn, increases the range in full-electric mode. Due to the modular structure of the hybrid transmission, it takes little additional space for installation, when compared to that of a standard gearbox. A main benefit of the hybrid transmission is that it is compatible with various engine sizes, and also offers all-wheel drive compatibility.

It should be noted that dedicated hybrid transmissions can be developed on the platform of a number of existing transmission concepts. These transmissions can be based on double clutch transmissions, conventional torque converter automatic transmissions, continuously variable transmissions or even automated manual transmissions. In any one of these cases, the electric motor is integrated into the transmission, with connection to different drive shafts. The type of hybrid transmission to be employed is determined on the cost of the overall vehicle, along with the level of refinement expected in putting down the power to the wheels.

This transmission electrification enables the actuation of gears shifting and releasing to be designed in a more efficient manner, so as to become more energy-saving in nature. Separate electric actuators can control the clamping and shifting separately, thus enhancing the overall efficiency of such transmission systems. Separate motors are equipped for the actuators, with the addition of oil pumps that further carry out the duties of cooling and lubricating transmission components. Therefore, it can be seen that dedicated hybrid transmission systems not only enable improved efficiency, but also add to the smooth operation of gears for a more comfortable driving experience.

COMPONENTS AIDING HYBRIDISATION

The need for hybridisation has led the industry to move away from or innovate some of the basic components that have been in use in the automotive sector over a long period of time, including starter motor, regulator and generator. The addition of automatic start-stop systems and 48 V electrical architectures, along with power electronics to address battery and electrification requirements has completely changed the layout of the vehicle platform of hybrids, when compared to conventional powertrain vehicles.

The newly-innovated components aim at offering OEMs solutions to achieve corporate average fuel economy (CAFE) targets that are specified by governments, in order to reduce emissions. These new-age systems that can be combined into hybrid vehicles as well as regular IC engine models, enable fuel savings and the integration of numerous components into singular units also enable weight reduction. While the reduction in weight may not be much when compared to the overall weight of the vehicle, they do result in small amounts of improved fuel economy.

ROUND-UP

The future of mobility will eventually transition to full electric powertrains, but this is a long-term goal of the industry. However, hybridisation is expected to witness extensive adoption across passenger and commercial vehicle segments in the near future. There has been increased development of both IC engines and electric powertrain systems across the globe, and the natural evolution of powertrains to address the growing requirements of emission and efficiency standards will be addressed by hybrid vehicle systems combining conventional and electric mobility.

(Inputs from SEG Automotive, Ricardo, ZF and Schaeffler)

By Naveen Arul

Source: https://autotechreview.com

CUT COTS OF THE FLEET WITH OUR AUDIT PROGRAM

The audit is a key tool to know the overall status and provide the analysis, the assessment, the advice, the suggestions and the actions to take in order to cut costs and increase the efficiency and efficacy of the fleet. We propose the following fleet management audit.