The Geely Icon, launched in February 2020, has new Intelligent Air Purification System (IAPS) that is N95 certified, the filtration level needed to block coronavirus. (Geely)

China’s Geely unveiled a new SUV with claimed N95-level cabin filtration – but that goes only so far in eliminating already unlikely coronavirus risks.

On February 4, millions of people across China – some sheltering in place – watched the online-only launch of the Geely Icon SUV. As the China-based automaker unveiled the new model, coronavirus-related deaths surged toward a reported 100 in Wuhan, China. Before the digital launch concluded, 30,000 per-orders had streamed in for the turbocharged, 175-horsepower Icon.

The overwhelming response to the Icon was based partly on its novel feature: an air-purification system certified to CN95 – the standard that approximates the same 95% filtering efficiency as a state-of-the-art daily N95 personal respiratory mask. Geely equipped the Icon’s air-conditioning system with a series of advanced filters. Some are aimed at filtering droplets and particles with 95% efficiency at the 0.3-micron level. Others use a bactericidal layer to “inactivate and kill the escaped virus,” as Geely states.

The anti-bacterial layer utilizes a nano-silver ion sterilization technology, while the anti-bacterial coating uses natural plant polyphenols to zap allergens. It’s a one-two punch. The impression conveyed by Geely’s announcement was compelling to consumers: game over for COVID-19 if you’re situated in the Icon’s futuristic interior. But can an air-filtration system, no matter how sophisticated, really keep every risk of coronavirus from invading the Icon’s cabin?

Careful what you claim

“I would be suspicious of any claims for effective ambient filtration that does not involve slightly pressurizing the cabin with filtered air,” said Werner Bergman, who served in 1994 on the SAE International committee working on standards for passenger-compartment air filters. Bergman is now the research director at Aerosol Science, an independent consultancy.

“Pressuring a cabin with high-efficiency – preferably HEPA grade – filtered air is the gold standard,” said Bergman. But he warned, “It is almost impossible to have a sufficiently sealed cabin or room.” Geely says its cabin has higher pressure when the air conditioner is blowing but admits that its cabins are not entirely sealed. Besides, as soon as one opens a door or a window, unfiltered air enters.

That’s not to say that Geely’s one-two strategy has no benefits. Nano-silver is commonly used to sanitize microscopic organisms, but it’s also a known toxic with environmental risks. Polyphenols are micronutrients derived from plant-based foods such as grape seeds; they are one of many types of anti-allergens.

Air-filtration basics

These additives can indeed be effective as part of a broad filtration strategy. But what’s more critical is the N95-grade of the raw material used in the Icon’s filter. That’s what ensures 95% filtration efficiency at the 0.3-micron level and the new SUV uses electrostatic meltblown media. Nearly all air-cabin filters are non-woven fabrics using long fibers bonded together, often with heat or chemicals.

But experts said that any discussion of the ability to filter viruses in vehicle cabins should focus on the fundamental rules of air filtration. The modern cabin filter is a relatively new innovation. It was first devised and commercialized in 1957 by Germany’s Freudenberg Group. In 1989, Freudenberg began producing its micronAir cabin-air filter for Mercedes-Benz – leading to millions of annual sales across the industry and a market-leading role that the company maintains today.

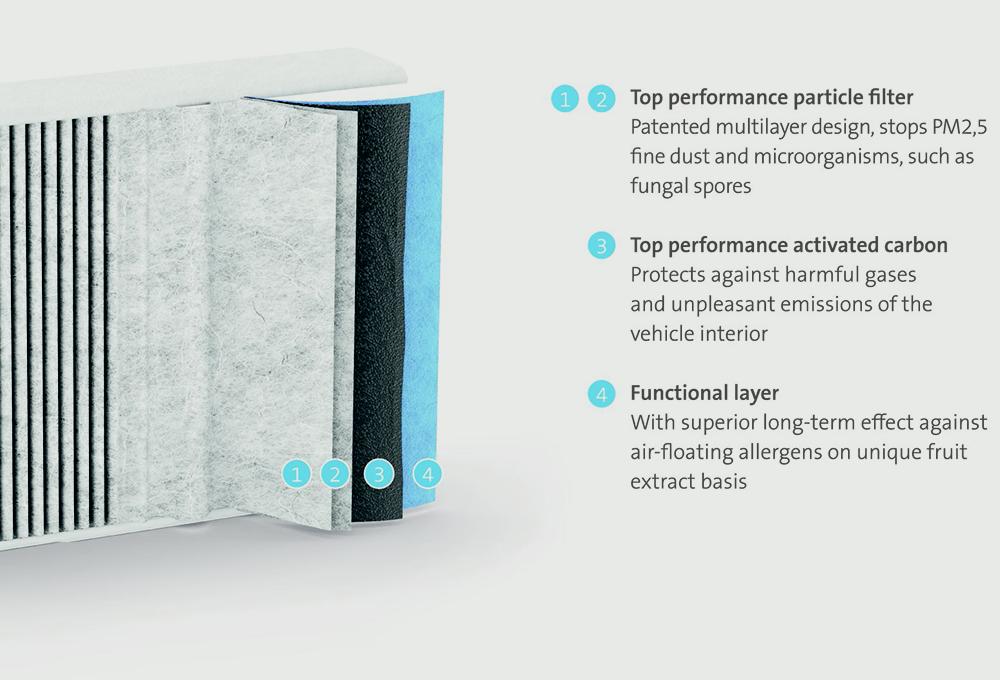

Volker Braeunling, global technical director of automotive filters at Freudenberg, explained the three essential levels of cabin-air filtration. The first is filtration-collection efficiency, the size of the particulate matter that’s captured. A progressive set of microfiber layers, each finer than the one before, collects the most harmful particles that passengers can breathe. “This microfiber layer is the most functional part,” said Braeunling.

Barry Kellar, Freudenberg’s global vice-president of automotive filters, said that in some automotive applications, pre-filters also are used. For example, vehicles operating on dusty roads might use a pre-filter to capture coarser particles. Because that material can build up fast, these filters are located where they can be easily replaced.

After filtration comes adsorption, a process by which a solid substance collects and contains gas. It often uses carbon to collect harmful odors and gases, thereby removing them from the air. Freudenberg opted for a custom recipe of activated carbon material, fine-tuned to specific adsorption properties.

Fruit extract and deactivating H1N1

It’s in the third so-called functional layer that viruses are addressed. Freudenberg’s Braeunling said, “We add a layer that has a specific impregnation of fruit extract to denature proteins, which are more or less also allergens.” In early March, Freudenberg tested the fruit-extract material using multiple third-party labs. “We received excellent results,” said Braeunling. “We tested the H1N1 influenza virus, and the deactivation rate was 99.99%. That means we could really deactivate all the viruses according to this test procedure.”

Braeunling explained that there are two different types of viruses: those with and without a protein-based envelope that protects the virus’s DNA. Freudenberg uses the fruit extract to destroy the virus’s shell, thereby deactivating the virus’s ability to enter the human body and to duplicate. However, filtering for viruses is also dependent on particle-size efficiency. The popular press describes coronavirus as very small, about 120 nanometers.

“But in the ambient air, you don’t see a single coronavirus flying around because these viruses are in the droplets coming from a human being who is sneezing or coughing,” said Braeunling. He explained that the droplets evaporate quickly, reducing the particle size to the one-micron level that can be inhalable, making them especially dangerous. “The filter must have a high efficiency to capture these fine particles and droplets,” said Braeunling. “A standard coarse filter isn’t good enough,” added Kellar.

Question all claims

Unfortunately, you can’t just fortify a vehicle cabin with HEPA-quality filtration; HEPA, which is a broad term standing for “high-efficiency particulate air,” is best applied to stationary applications such as hospitals or plants that manufacture electronics. Unfortunately, HEPA is becoming a marketing term casually applied to household products like vacuum cleaners.

The term HEPA is similarly unhelpful for cabins of vehicles, where the air filtration system fights for real estate with other automotive content. A personal N95 mask can provide a degree of protection against viruses, but think about how it inhibits the user’s air intake. Automakers have to ensure the filtration is not too restrictive, which can result in pressure drop. Passenger comfort largely is based on the generous flow of air. To avoid that feeling of having something pressed against the face yet maintain effectiveness compared to a mask, cabin-air filters have increased surface area.

A typical cabin-air filter is around 9 inches by 8 inches by 1 inch. Pleating the material can expand the area by about ten-fold. The goal of reliably filtering coronavirus from a vehicle cabin has myriad challenges. The efficiency and adsorption functions, the need for effective and safe anti-allergen additives and the form factor of the filter all must work as a system – one that’s comfortable for passengers using the vehicle’s air conditioning and that can be industrialized by manufacturers. There’s no silver bullet.

That said, Freudenberg’s Kellar stops short of dismissing all COVID-killer claims. “You can’t carte blanche say that everybody claiming they have a system to prevent coronavirus is misleading consumers,” he said. “We couldn’t say that because we don’t know.” Until verifiable lab tests accompany those claims, and unless strict rules about practical everyday use are honored, expectations should be tempered, he said.

Perhaps more importantly, the potential for coronavirus to enter a vehicle is extremely unlikely. “I can’t think of any circumstance where the outdoor COVID-19 concentration is so high that one needs a vehicle filtration system,” said Bergman.

Source: https://www.sae.org

CUT COTS OF THE FLEET WITH OUR AUDIT PROGRAM

The audit is a key tool to know the overall status and provide the analysis, the assessment, the advice, the suggestions and the actions to take in order to cut costs and increase the efficiency and efficacy of the fleet. We propose the following fleet management audit.