It may be time to revisit how your company produces and delivers products as consumers and retailers become more environmentally aware and shift to a circular supply chain.

According to National Geographic, about 8 million pieces of plastic find their way into the oceans each year, which is the equivalent of putting five garbage bags full of trash on every foot of coastline around the world. Millions of animals are killed from entanglement or starvation because of microplastics, which are ingested by fish and block their digestive tracts or pierce their organs. A new Scientific Reports study even suggests that the fish that end up on your dinner plate could expose humans to microplastics and their harmful toxins, such as heavy metals and organic pollutants.

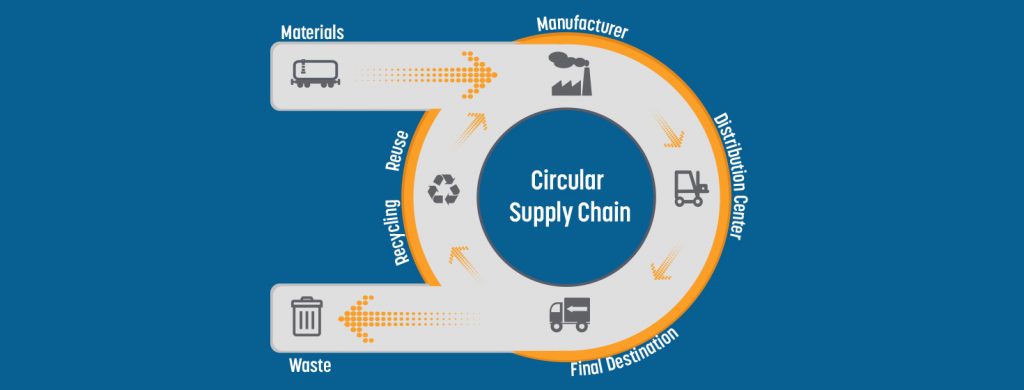

Plastic is just one type of waste that, if not recycled, reused, or remanufactured, ends up in landfills and pollutes the air, land, and water. Unfortunately, developing recycling initiatives, managing groundwater contamination, and complying with environmental regulations drains a lot of cash from municipalities and taxpayers. The good news is that companies and consumers are becoming more environmentally aware and shifting from a traditional linear supply chain to a circular one. By reducing the demand for manufactured products, we can reduce the toxicity and volume of waste that end up in landfills.

The Circular Economy

The circular economy attempts to minimize the input of resources and the generation of waste leaking into the environment. The goal is to reduce the number of primary raw materials used and get as much out of them as possible to prevent waste. Then we look to recycle, remanufacture, or reuse the product.

- Recycle: Collect materials so they can be used to manufacture new products.

- Remanufacture: Take an existing product that has ceased to function from wear and tear or damage and refurbish or replace its components, and then reintroduce it into the supply chain.

- Reuse/resell: Transfer or sell products from one user to another.

The circular economy will change many things for companies in the supply chain. Companies need to revisit how they produce and deliver products as retailers and consumers demand more environmental awareness.

Four Things to Consider Before Kicking Off Your Sustainability Project

- Circular inputs: How can you change your materials to ones that are renewable or recyclable, and how can you use fewer materials in the initial manufacturing process?

- Product design: How can you design products to last longer or perhaps to be used in a sharing system? How can you design products that can be easily disassembled at the end-of-use stage without expending immense labor or energy?

- Process design: When looking at your processes, how can you make the product with renewable or recycled materials?

- Circular flows: At the end of use, how do you recover materials or products so they can be used again?

Business Models Enabling Circular Supply

Many new business models are emerging to manage circular flows. In South Africa, for example, where unemployment is extremely high and there are no sophisticated recycling services in place, people walk from housing complex to housing complex collecting plastic, paper, and glass, which they take to the recycling plants and are paid per ton. On a more global scale, Uber provides a platform to provide transportation only when it’s needed. This model beats having a five-seat car in the garage that transports one person for an average of two hours per day. Companies that sell solvents as a service is another business model enabling circular supply. They can control the usage of the solvents, recover the remainder, clean it up, and reuse it for other purposes.

Flea markets and boot sales are still popular models for recycling and reusing goods. This concept of a “market” where people can go to buy and sell has led to companies such as eBay, Gumtree, Craig’s List and Facebook community groups popping up to provide an online platform to do the same thing—assist in the selling of previously owned goods.

Some retailers are attempting to reduce their packaging footprint. New Zealand supermarkets have started “food in the nude” campaigns, whereby all their fresh produce is sold without packaging. South Africa’s Pick n Pay is piloting a packaging-free shopping zone in their Cape Town location. The zone consists of dry goods such as baked goods, cereals, dried fruit, grains, ground coffee, nuts, pasta, and rice. Customers are encouraged to bring their reusable containers, or the store provides free paper bags and reusable containers that can be purchased. The absence of packaging means lower costs for the retailer as well as the consumer.

Enablers and Accelerators

Enablers and accelerators are systems and technologies designed to recycle or remanufacture. Technologies such as 3D printing, big data, the Internet of Things, and different ways of thinking, like green chemistry, are just a few means of supporting a circular economy.

Start Your Journey

If you are planning a greener future, start by taking small steps in the right direction. As opposed to restructuring your entire business, start with short-term projects and reinvest the benefits into long-term wins. Consider developing a business model in which you take back and remarket your products. If you don’t take back your goods, then you can’t profit from the end-of-use stage. Designing smart goods that are environmentally friendly only to have other businesses benefit at the end of use doesn’t make too much sense. You can then decide whether to recycle, resell, or remanufacture your products.

Get More Value from Your Waste

What can you recycle from end-of-use products and waste along other points of the supply chain? If you are a food manufacturer, for example, are you using all your raw materials? Are there bits left behind that can be used as a by-product for another product? Perhaps another business in a different industry has a use for one of your by-products. The object is to try and use up as much of your raw materials as you possibly can so you can maximize profits and minimize waste.

As an example, let’s look at oranges. Two primary products exist—the whole fruit and the juice of the fruit. However, there are many by-products from the orange that can be used or sold to other manufacturers.

- Peel oil: Manufacturers use this for the production of various flavor compounds in the beverage, cosmetics, and chemical industries.

- Essence oil: Flavor companies commonly use this to make mixtures for the food and beverage industry.

- Peel: Pectin, found in the orange peel, is used as an ingredient in jam, marmalade, and jelly.

- Citrus molasses: This is used in the production of animal feed pellets or as raw material for citrus alcohol via fermentation.

- D-limonene: Found in the orange peel, this oil is used by the plastics industry as a raw material for resins and adhesives. It is also found in the electronics industry, where it is used as a solvent.

Get More Value from End-of-Use Products

What options exist for a product at the end of its use? Is it fit for reuse or resale? If it can’t be resold, maybe it can be repaired, refurbished, or remanufactured.

- Processing inputs: Look at your processing inputs, such as water and energy. Are you bringing them back into the process? If not, could you?

- Waste consolidation: Could you consolidate your waste flows with other companies in the area? This will turn a cost into a revenue stream as you collect more waste volume, and by bailing it up, you would make it worth something to a waste buyer.

- Offcuts: If you are in discrete manufacturing, what are you doing with your offcuts? Could they be used to build another product, or is there an opportunity to sell offcuts to other companies?

Companies in the packaging industry are under heavy scrutiny, specifically plastics packaging manufacturers. These companies will have to look at alternate business models. With supermarkets promoting packaging-free shopping, packaging companies will need to find alternative ways to package or deliver their products. Consumers are becoming more and more aware of the hazards that come along with packaging, and it won’t be long before all products are sold without fancy packaging.

All other supply chain companies should look carefully at their current business model and see if they, too, are under threat of extinction in a circular supply chain. If you think you are at risk, you may need to reinvent yourself. Professor Walter Stahel sums up the benefits of a circular economy when he said, “The goods of today become the resources of tomorrow at yesterday’s prices. So, let’s all do our bit to make this a reality.”

By Barry Kukkuk, CTO, NETSTOCK

Source: https://www.inboundlogistics.com

CUT COTS OF THE FLEET WITH OUR AUDIT PROGRAM

The audit is a key tool to know the overall status and provide the analysis, the assessment, the advice, the suggestions and the actions to take in order to cut costs and increase the efficiency and efficacy of the fleet. We propose the following fleet management audit.