Extraction of the Nexcel module in the Toyota Prius demonstration

vehicle.

BP’s Nexcel sealed-cell oil system an alternative for controlling GHG emissions

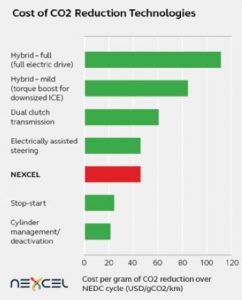

The automotive industry is broadening its spectrum of technology to support the reduction of global greenhouse gases not just via electric drivetrains and downsized ICEs but by exploring more non-mainstream solutions. One of those is BP’s Nexcel sealed-cell oil-management system, which is being further developed to work in tandem with hybrid drivetrains. The innovation business claims it can deliver a cost benefit able to compete on a $/g CO2-saved basis with more conventional environmentallyfocused technologies.

Nexcel claims its system is markedly less costly compared to mild hybridization, and instead of becoming a competitor, it sees a combination of the two delivering a significant environmental benefit. Nexcel is now focusing its development work on linking its system with hybrid drivetrains to achieve significant environmental gains. To make the point, it has developed a Toyota Prius demonstrator (above) using its oil management system as a genre-representative vehicle (it is not in partnership with Toyota) to support the results.

Targeting greenhouse gases In volume production with economies of scale attained, Nexcel claims its self-contained system’s unit cost would be about half that of electric power steering (EPAS). As previously reported, the system provides a sealed cell containing the correct grade of oil and specification of filter for a particular engine type, an integrated pump and electronic control unit that communicates with the vehicle. “Testing of the system has confirmed its potential to reduce CO2 by 2g/km,” claimed Nexcel’s Sustainability Director John Ward-Zinski. “The reduction is delivered by ensuring a precise oil-engine match, helping the oil to warm up more quickly and boosting its active components between oil changes.”

Nexcel expects initial applications of its technology to reduce CO2 emissions for a cost of around $50/g. Ward-Zinski said he believes active oil management technology’s potential will see it taking a similar development trajectory to that which led to EPAS, initially also an outside-the-envelope solution to emissions reduction but now almost ubiquitous.

Ward-Zinski stated that the EC’s “own impact study and indications from U.S. observers such as FEV” point to a prediction that mild hybridization will be significantly more costly than the latest Nexcel system for each gram of CO2 saved, while full hybridization carries a cost over twice that of the Nexcel system.

Nexcel expects the cost of its systems’ CO2 reduction to potentially lower to around $25/g in fully-integrated, high-volume applications.Nexcel’s $50/g estimate for an initial highvolume application is based on a combination of bill of materials and manufacturing costs. $25/g is Nexcel’s indicative target for a high-volume application with further economies achieved through increased levels of integration with the vehicle early in the design.

Warming up to it

As engine efficiency improves, the warmup period becomes proportionately more significant for emissions, said Steven Goodier, Program Director and founder of Nexcel. Even in the Worldwide Harmonized Light Vehicle Test Procedure (WLTP) test cycle, a significant proportion of the measurement is conducted with the engine at less than optimum operating temperature, which means it is producing more CO2 and more pollutants.

“By reducing the volume of oil in the engine sump during cold start, the Nexcel system enables faster warm up,” Goodier explained. “Every liter of oil removed has a heat capacity equivalent to around 2 kg of aluminum or 4 kg of cast iron, so transferring oil to the cell when it isn’t needed helps bring engines up to their optimum temperature more quickly.”

Although the viscosity of engine oils is being reduced to minimize energy losses and cut CO2 emissions, the biggest contribution to viscosity often comes from the additives in the oil, which are present in sufficient amounts to permit the longest extended service intervals, explained Ward-Zinski. He said an aim of the Nexcel system is to “change the rules by boosting the oils’ additive content between services”, so preserving its effectiveness.

Motivations vary

Nexcel examined hybrid-vehicle-buyer motivations in seven countries (U.S., U.K., France, Germany, Japan, China, South Korea), where researchers found environmental concerns were a top motivation in the U.S., while fuel economy and government incentives were key European factors.

Nexcel examined hybrid-vehicle-buyer motivations in seven countries (U.S., U.K., France, Germany, Japan, China, South Korea), where researchers found environmental concerns were a top motivation in the U.S., while fuel economy and government incentives were key European factors.

Japanese and South Korean attitudes were similar to those of Europeans. In China, government purchase incentives were the main reason for the purchase of hybrid-electric vehicles. “Hybrid-buyer motivations around the world vary, but all are concerned about the whole life impact of their vehicle choice, both environmentally and economically,” Ward-Zinski noted.

“Because this resonates with Nexcel’s benefits, it encouraged us to produce a research paper on development and market context regarding projected hybrid EV development over the next two decades and where Nexcel technology would be relevant.”

One of these is packaging. The sealed oil cell allows for a reduced ICE sump capacity to facilitate a shorter engine with no requirement for sump drain access. This would provide benefits including battery storage under the engine, or lower engine mounting that could lead to aerodynamic and pedestrian safety improvements. With the oil filter now housed in the Nexcel cell, designers would no longer be required to provide space around the engine block for conventional oil filter replacement.

Ward-Zinski also cited benefits for ICE range extenders, stating that because they are not mechanically coupled to the wheels, the use of the Nexcel system, combined with other established technologies such as an electric water pump and remote induction, could allow the placement of the ICE in relatively inaccessible but efficient locations, but said “don’t expect the ICE in the glovebox any time soon!”

Written by Stuart Birch

Source: Automotive Engineering

Automotive Engineering magazine is the No. 1 resource for engineers across multiple disciplines in the automotive industry. Published 10 times annually, Automotive Engineering engages decision makers who buy and specify product. Each issue includes special features and technology reports, from topics such as: vehicle development and systems engineering, powertrain and subsystems, environment, electronics, testing and simulation, and design for manufacturing.