The past few years have been full of solutions to solve some of the more common reefer unit issues.

Battery and starter issues are two of the most prevalent issues affecting transport refrigeration units (TRUs), according to Christopher Tate, general manager of Thermo King dealer Mohawk Truck, and two-time TMCSuperTech grand champion.

Preventive maintenance is the first line of defense, but plenty of cold chain vendors have added technological tools to bolster those efforts and mitigate unplanned downtime.

Here are a few of the latest developments.

Electric TRUs

A big trend as of late is running TRUs off battery power over over diesel fuel. The most obvious advantage is a lower fuel bill as eTRUs typically run off the battery on the road and can plug in at docks and staging areas to eliminate idling. And because of the fewer moving parts, they require less maintenance. These can work in conjunction with electric or fossil fuel truck powertrains.

Regulations might also necessitate the move. California’s anti-idling regulations for TRUs are a main reason ConMet launched its zero-emission reefer trailer solution.

“The California Air Resource Board has taken notice of TRUs, and they are looking at legislation in 2025 to ensure that TRUs are zero emissions, so we have to find solutions to do this—and time is getting really short,” said Marc Trahand, VP and general manager of ConMet eMobility, at American Trucking Associations’ Technology & Maintenance Council 2021 Fall Meeting & Transportation Technology Exhibition in Cleveland.

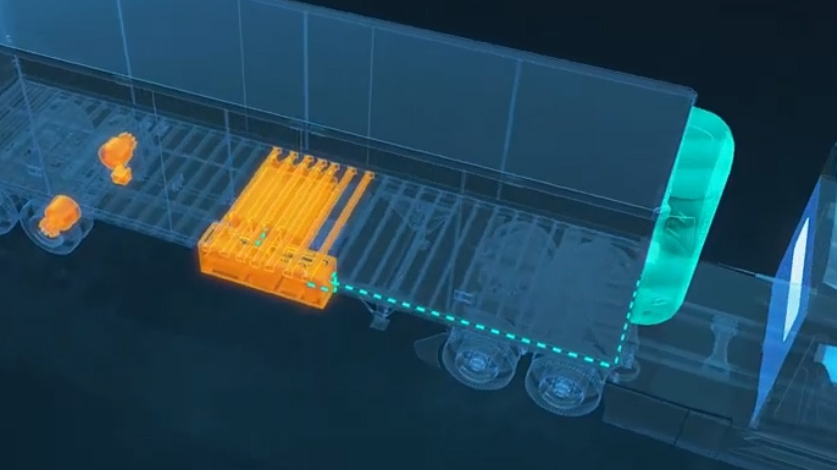

Using Preset Plus Electric Hubs, battery module, and eTRU, the system can recharge on the road via regenerative braking, as well as assist in pushing power.

According to ConMet, a reefer tractor-trailer could save $7,500 annually, two-thirds of that coming from decarbonizing the TRU. The use of regen braking also will reduce some wear and tear on the braking system, while the power-assist feature, which can improve tractor fuel economy by 20%, will help on the engine side.

For light- and medium-duty, Thermo King released the E-200 eTRU earlier this year. Benefits include a power management system for lower energy consumption, variable speed compressor for precise temperature control, and the ability to run independent of the engine.

“The E-200 represents the next generation of all-electric refrigeration units,” said Tracey Patterson, truck product manager for Thermo King. “It provides our customers with refrigeration that moves beyond direct drive systems and helps them meet their sustainability targets throughout the cold chain.”

To create true zero-emission cooling without the need for a fully battery-electric vehicle, Thermo King has provided two lithium-ion battery options for the E-200—1.8 kWh and 3.6 kWh.

Solar panels

To locate the easiest energy source on Earth to tap, just look up (but don’t stare). The sun nourishes nearly all life on Earth, and can provide some extra juice to charge TRU batteries and prevent them from draining to exhaustion.

“A solar panel is now one of the top five options ordered by our customers,” noted Tom Kampf, Thermo King senior product manager for trailer to Fleet Maintenance earlier this year. “Our [ThermoLite] 30W solar panel can mount to either the trailer or the TRU itself. The solar panel helps keep the battery topped off so the TRU can restart after its off-cycle rest.”

Recently, Carrier Transicold released the TRU-Mount Solar Charging System, which sits atopCarrier Transicold X4 and X2 and Vector 8000 and 6000 series TRUs. Via ultrapure silicon cells and a high-performance charge controller, the system feeds 2.0-amp power to completely charge a 12V TRU battery

Looking ahead, a London-based company called Sunswap is developing a zero-emission TRU that relies on a solar array on the trailer that provides up to nearly half of the TRU’s power, as well as its proprietary Adaptive Battery Capacity technology. This modular approach to onboard energy storage allows fleets to customize based on needed battery capacity. The system will also use a ultra-low Global Warming Potential refrigerant. Road tests were planned for this year in the United Kingdom. If successful, this will likely be a solution rolled out in California ahead of those potential 2025 zero-emissions TRU regulations.

Starters

Having your car not start in the morning is annoying and inconvenient—and could really set back your day. Having your reefer unit not start could begin a cold chain reaction of dozens of inconveniences, from the driver to receivers to the end customers.

Last year, Purkeys launched the 10-lb. SteadyCharge Accessory Battery Charger to monitor and maintain an optimal charge level, ensuring the battery doesn’t deplete during inactive periods. This can happen from natural discharge or even from a combination of parasitic current draw from telematics and extended inactive time.

SteadyCharge connects from the trailer to the tractor via the 7-way cable.

“Many large fleets spend millions of dollars on battery maintenance and replacement annually, and that’s not including asset downtime,” said Jimmy Fielding, Northeast account representative for Purkeys. “Not only will the SteadyCharge significantly reduce battery maintenance and repair costs, it will keep vehicles and drivers on the road by extending the lifespan of existing batteries by up to 500%.”

Telematics

“Carrier Transicold’s eSolutions platform can help dispatchers quickly locate and place into service refrigerated trailers that are idle,” Bill Maddox, senior manager of product management for Carrier Transicold, said. “Fleets can also monitor a trailer’s interior for temperature compliance during transit.

“When a fleet keeps a watchful eye on TRU operating modes used throughout the fleet, managers can optimize fuel efficiency by identifying opportunities for greater use of fuel-saving stop/start mode versus continuous-run,” Maddox explained. “Fleets can also track the extent to which their TRUs operate via electric standby when parked, helping to document the resulting fuel-cost savings. Also, centralized records generated on fuel consumption can be used to recoup direct costs through customer invoicing.”

Meanwhile, TLD Logistics Services has found success with ORBCOMM’s in-cab and cold chain telematics solutions, which help track driver performance and hours of service, while also providing two-way temperature monitoring and control, fuel management, maintenance, and logistics services.

Fully electric solutions

In 2019, Thermo King started offering offers a fully electric reefer van through Chanje called the V8100. The electric vehicle uses the Thermo King V-520 RT refrigeration unit and ThermoLite solar panels.

And this summer, the company announced an electric Class 1 refrigerated van with Electric Last Mile Solutions. This pairs the E-200 with ELMS’ Urban Delivery van. The battery provides 42 kWh and an estimated 150-mile range.

The maintenance benefits will extend from the TRU itself to the overall vehicle.

“The current technology with that compressor mounted to the engine is very susceptible to wear and tear, because if the engine rpms [are] really high, you can overstress the system; it’s very hard to regulate,” said Paul Kroes, Thermo King market and technology insights leader. “Now, with a self-contained system that’s running off of steady-state power input, the reliability goes through the roof compared to current architecture.”

The unit is expected to be available by the end of 2021.

By John Hitch

Source: https://www.fleetowner.com/