The company is showcasing a 100% electric system designed for tractors, scalable and with power outputs between 60 and 100 kW.

Electrification isn’t limited to our roads. Heavy machinery is also a significant source of pollution, which is especially counterproductive when it comes to agricultural equipment, given its contact with nature and the food we eat. The technology company ZF has taken a major step in the electrification of the sector with the development of eTERRADRIVE, a modular and integrated transmission system designed for electric tractors.

According to the manufacturer, it can offer power outputs between 60 and 100 kW, has a single drive unit, mechanical power take-offs (PTOs), and a working hydraulic system, in addition to the rear lift. Furthermore, it has a compact size designed for installation on relatively small vehicles (within the industry).

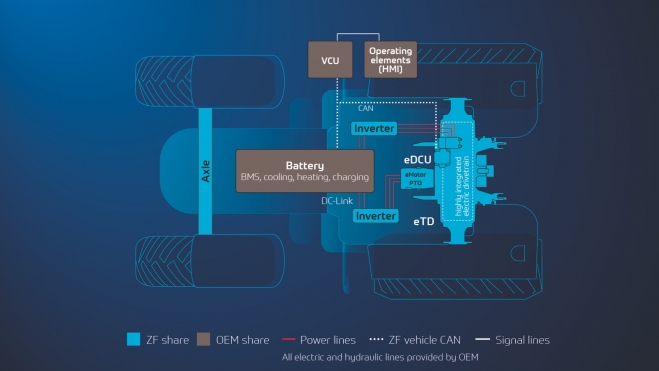

The internal structure of the ZF eTERRADRIVE.

Compact and Modular Design for Maximum Flexibility

The company is clear about its approach: “A compact design was prioritized to ensure maximum installation flexibility on various vehicle platforms and track gauges. Its modular and compact architecture offers broad applicability, from specialized crops to municipal and conventional farms.”

The system aims to be applicable to the widest possible range of platforms, and what’s remarkable is that it won’t be limited to new vehicles. ZF has ensured full compatibility with the interfaces of existing models on the market, facilitating its integration into current machines without requiring extensive redesigns. Thanks to this, it is considered an attractive alternative for manufacturers and operators looking to advance electrification without compromising their existing product range.

The new transmission system incorporates an advanced electronic architecture, based on an additional control unit (eDCU) that communicates with existing vehicle systems, such as the Transmission Control Unit (TCU) and Vehicle Dynamics Control (VDC). Furthermore, ZF has integrated specific safety features for high-voltage systems, particularly designed to meet the needs of off-road applications.

A New Twist in Electrification

ZF’s system changes the format typically used in electrified tractors. Generally, they employ hydrostatic CVT transmissions in which an electric motor replaces the combustion engine. It was a simple solution to implement, but the brand points out that it has limitations: high mechanical complexity, greater energy losses, and reduced scalability.

The eTERRADRIVE tackles the problem from a new perspective. It integrates two oil-cooled synchronous motors and a planetary gear set. This configuration improves operating efficiency, allows for more precise torque control, and optimizes energy use. Furthermore, its compact design frees up more space for energy storage, enabling the installation of higher-capacity batteries or hydrogen tanks, thus achieving greater autonomy.

It should also be noted that the eTERRADRIVE offers all the functionalities of a conventional tractor, including energy recovery during operation, without sacrificing power or performance, and with the added benefit of zero emissions, which has significant environmental advantages.

In summary, ZF lists the main advantages of its system:

- Complete zero-emission operation

- Reduced mechanical complexity and maintenance

- Greater energy efficiency

- Scalable platform adaptable to future vehicle concepts

- Full compatibility with current interfaces and safety standards