Leveraging task management tools can help fleets’ maintenance operations plan ahead, which is helpful amid technician and parts shortages.

Efficient fleet maintenance operations today have multiple software options and methods to collect the data relevant to incoming jobs, such as vehicle identification numbers, driver complaints, and other necessary information as a vehicle enters the bay. That information is then compiled into the shop’s system, where technicians and maintenance managers can search for top fault codes and delegate the right technician to perform the job.

Broadly speaking, this software, known as task management tools (TMT), can be as simple as a spreadsheet—with smaller shops using Quick Books or Xcel—or take the form of a highly advanced platform using predictive analytics.

These predictive technologies are being used to inform fleet maintenance and repair departments about multiple issues that can be addressed in one shot rather than making the vehicle return to the service center several times over a two- or three-month period. They also inform maintenance departments about likely future problems, giving fleets a chance to schedule vehicle maintenance before a catastrophic event occurs.

Planning ahead

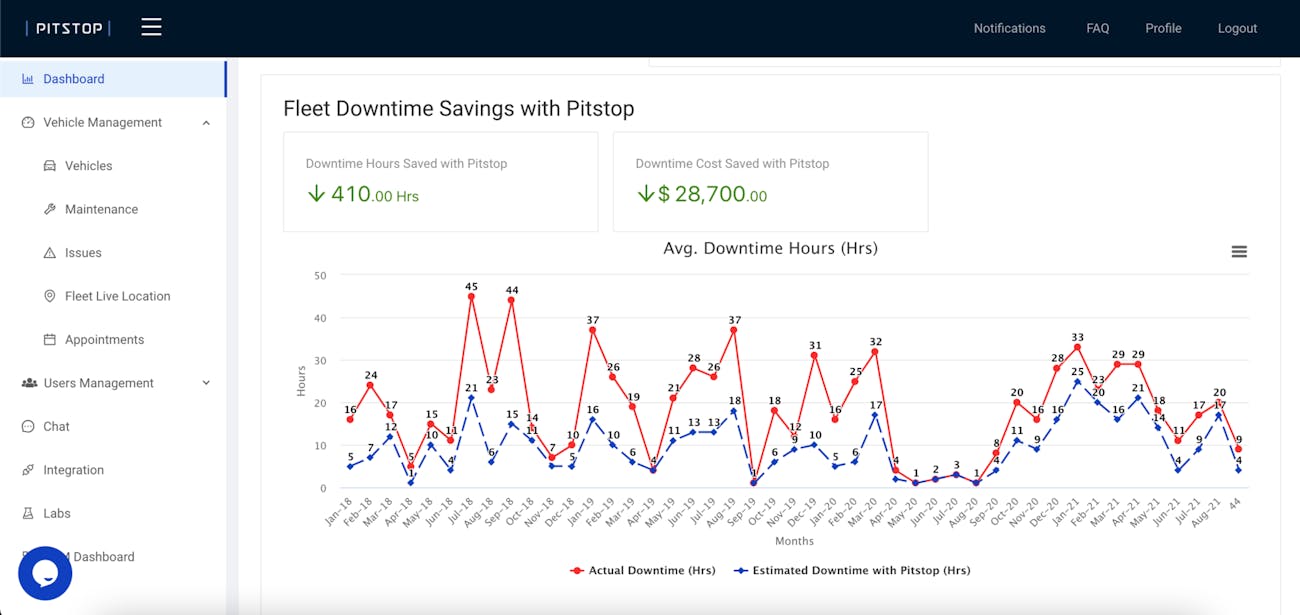

Shiva Bhardwaj, CEO of Pitstop Connect, a platform powered by artificial intelligence (AI) and machine learning (ML) to predict potential truck component failures weeks before they happen, emphasized that a fleet’s best bet is to use technology to plan downtime and minimize pain points related to unexpected downtime.

“Though fleet managers know they need data to make efficient predictive maintenance decisions, they fail to mine datasets to develop insights,” Bhardwaj said. “An effective fleet monitoring system leverages the power of AI, ML, cloud data storage technologies, and big data analytics to make accurate forecasts and assist technicians in identifying faults.”

See also: The evolution of truck telematics, connectivity

Pitstop software, for example, provides fleets with a vehicle health score, informing maintenance operations of their top 15 high-risk vehicles. “Those vehicles will continue to cause downtime,” Bhardwaj said, adding that the software generates reports that are automatically sent to partner service centers and drivers as needed.

Bhardwaj added this “lessens manual work and calculations, leaving little room for errors. No routine inspections are required since your [predictive maintenance] software has already conducted full diagnostics and shared the real-time vehicle health report with fleet managers.”

Trimble Transportation offers a TMT software solution that provides communication between the driver and maintenance operation as events happen on the road.

“By having that communication between the driver, the operation, and maintenance, we can increase our uptime, and planning and scheduling the work,” explained Renaldo Adler, head of software engineering, connected maintenance, Trimble Transportation. “If you look at predictive analytics and communicate that to operations, there is a probability we can schedule the truck.”

The same goes for an in-house repair, Adler said. Fleets can schedule a repair within Trimble’s software to ensure the truck gets fixed quicker.

“Operations can schedule it through our software, which has a tool that sends the mechanic the right information available to get that truck back on the road,” Adler said. He also stressed the need to know what parts and technicians are required to complete the job.

Another plus is that modern software can be wireless, allowing for over-the-air updates when a truck on the road requires an update or calibration of some sort, noted Willie Reeves, Paccar Leasing’s director of franchise maintenance.

“It can be done wirelessly instead of bringing the vehicle in or going to a customer’s yard and plugging in the laptop,” Reeves said. “It doesn’t interrupt a driver coming and going.”

Technician, parts management

Even the most organized fleet maintenance operations are struggling to get trucks up and running because of ongoing technician and parts and component shortages.

The U.S. Bureau of Labor Statistics reports some 28,100 openings for diesel technicians are projected each year, on average, over this decade. Inflationary pressures have also caused a spike in commercial vehicle equipment prices, with prices being passed down from suppliers to their fleet and dealer customers.

But this is temporary, Pitstop’s Bhardwaj said. When things smooth out a bit, he said he believes there will be a technological leap to help improve labor scheduling and maintenance management.

“You could probably plan 80% of the labor times more effectively,” Bhardwaj said, “because you have the data from the actual truck that’s coming in. Fleets can use it as a benchmark against how other people have done service. The technology can get us there, but I think it will take some time.”

See also: Suppliers set sights on enhancing tractor-trailer connectivity

Future technician training will likely pivot as well, with less of an emphasis on training about what certain fault codes mean, and more around how to use software and when to make what decisions based on the data. The next step will be fitting the appropriate data into existing maintenance workflows.

“Then, things like ordering parts ahead of time and scheduling service with more accuracy ahead of time are the types of scenarios that get enabled once these solutions are adopted at a higher frequency,” Bhardwaj explained.

Ultimately, it will be about feeding back vital information to the fleet and the service center so all players can stay up to date on stock inventory, recalls, and warranty trends.

Trimble does something similar today through its integration with TravelCenters of America. If there is a condition on the road, Trimble can make a request from its software directly into TA’s system to inform maintenance operations when the driver will be in with the truck as well as the parts needed to turn that vehicle around quickly, Adler said.

Trimble also designed a tablet for technicians that tells them the trucks they need to work on, vehicle specs and history, and inventory needed from the parts department.

Adler explained the tablet has a common user interface to eliminate training, as technicians simply scan parts and key in numbers. The tablet also serves as a time clock for workers to manage their time throughout the day, and revisit how much time is spent on specific tasks, like changing tires and fixing brakes.

“Trucks are harder to fix now,” Adler said, noting technicians today need to be more tech-savvy and use more digital tools to fix a truck. “They need more electronic data. As it becomes a more technical job, hopefully it will bring more people into that field.”

One system PacLease is rolling out to help with the technician shortage is a voice-guided PM product to help train incoming technicians on how to perform preventive maintenance intervals. With voice-guided headsets, the system shows technicians how to start a PM and then has them follow modules online.

The system aims to standardize PMs for every PacLease location. “It also eliminates and removes someone from having to show someone else how to physically do a PM,” Reeves said. “With that, you gain that person working in the shop rather than as a PM trainer, and it opens that person up to do more scheduled maintenance.”

As part of its managed maintenance program for leased customers, PacLease schedules PMs and any repairs that need to be made so fleets don’t have to manage that themselves.

“We really don’t see big mechanical issues happening on units,” he said. “It’s mostly the electronics. Those are the things we use to give us feedback on how the unit is performing.”

In today’s world with parts shortages, Reeves said PacLease is trying to be more proactive with its units, as it can take anywhere from a week to a month to procure a specific part.

Being proactive also means PM consistency. To keep things consistent, PacLease integrates with Kenworth’s TruckTech+ and Peterbilt’s SmartLINQ remote diagnostics and telematics solutions.

“Information goes back to the fleet manager, who is managing that crucial data, and it gives them the capability to check the units in their fleet,” Reeves pointed out. “If they have a fleet of 20 trucks, they can see how those 20 trucks are doing and compare the data between the trucks.

“It gives them the opportunity to move trucks around if they have a truck that is running high miles on their lease program,” he added. “They can move other trucks to that area to keep the mileage down.”

These days, Reeves is seeing more and more trucking companies leasing because of the rising price of commercial vehicle equipment. He added that because there are not that many trucks available in the market, companies also are holding onto their used assets versus turning them in—making PMs even more important.

Fleets today are also battling rising diesel and oil prices, so managing idle time can be incredibly important for overall total cost of ownership. One of the parameters that fleet managers can view in their software is idle time, Reeves said.

“You can see how long a vehicle is idling throughout the day, and you can come up with best practices to help reduce the idle time,” he said. “Most of the idle time is done by percentages, so some units that are running regional might have a higher idle time than those running over the road. It gives managers the opportunity to decrease the idle time and keep the trucks from burning so much fuel.”

This article originally appeared in its entirety on Fleet Maintenance, FleetOwner’s sister publication and part of the Endeavor Commercial Vehicle Group.

Source https://www.fleetowner.com/