Best practices for technicians when the time comes to fix damaged wiring.

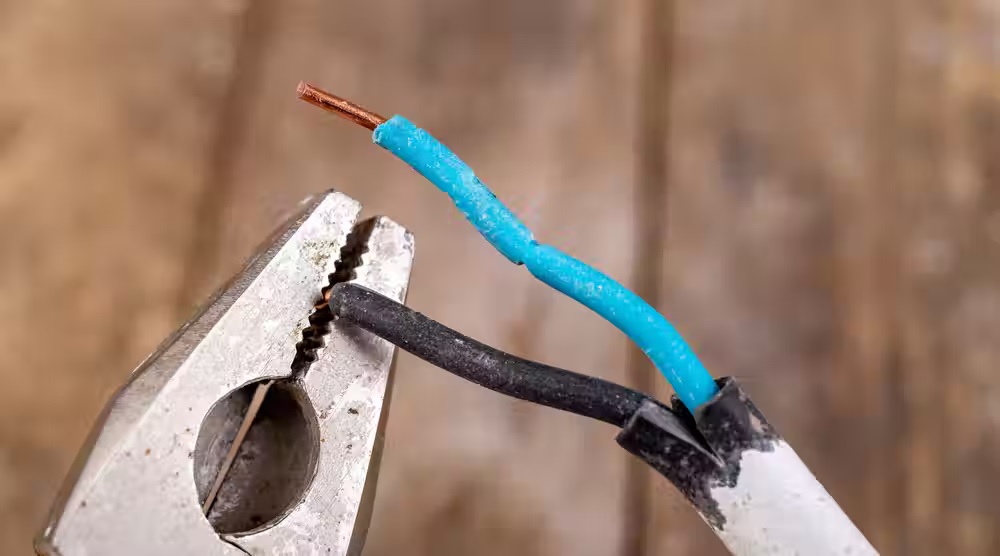

So, what to do when damage to wiring is detected? If it’s greater than 10-gauge, TMC RP 186 recommends replacement. For low-voltage J1128 wiring 10-gauge and under, a proficient technician can splice and fix. Tools needed include wire cutters, strippers, soldering gun, dual wall polyolefin heat shrink tubing rated 257 degrees Fahrenheit, and a heat shrink gun.

There are two suggested splicing techniques: the J-hook or the Lineman’s splice. For the J-hook, slide the heat shrink over one side, remove the damaged wire, and strip away 3/8-in. of insulation on each end. Curve the wire ends into a “J” shape and hook them together. Twist the tips around the opposing wire and give them a tug to ensure tightness.

For the Lineman’s splice, strip a half inch of insulation and cross the wires, and bend the ends over each other several times. In both cases, solder over the new connection, remove any burrs, and slide the sheath of heat shrink over the area and blast away with the heat gun. Then test the circuit.

TA Truck Service Master Technician Lucas Coyle, who earned top spot in the lighting category at TMC SuperTech 2021, found heat shrink insulated solder butt connectors provide a quick and easy alternative solution.

“This does not require crimping, so there is little room for damage to the shrink insulation,” Coyle said. “The connector requires just a clean cut, stripped wires, and a heat gun.

“I use a helping hand tool that holds both wires still with alligator clips while I make the repair,” he added. “That way, the solder has time to solidify. Depending on the location of the needed repair, these can be difficult to use without removal of the harness or wiring section.”

A little more time invested now can pay dividends in the future.

“The extra time spent on a quality repair is always worth it in the long run,” Coyle offered.

By John Hitch

Source: https://www.fleetmaintenance.com/