Spills happen. Maybe not often, but shop managers should accept that they can—and someday will. Knowing there will be spills is only the first step in maintaining a safe, clean, and efficient shop environment. But it will take more than that to create a successful cleanup and containment plan. All shops are different, and they all won’t be spotless, as commercial vehicle maintenance is full of greases and oils and fluids waiting to hit the floor. But the following steps will allow the shop to react better and faster to such spills, while also promoting employee safety and a clean, professional look.

Assess the environment

“Our main effort is to make sure that there isn’t a spill to clean up in the first place,” said Jessica Smith, health and safety specialist at Rush Enterprises, speaking on the company’s spill-handling strategy.

To do this, Smith said supervisors should take time to understand when and where spills could take place, what could spill, as well as how severe a potential spill could be. This includes estimating the quantity of fluid that could be spilled.

“Step one, we evaluate our on-site potential spills: things from the truck, their storage capacity, and their condition,” she explained. “Next, we’re going to identify potential discharge scenarios. Can the tank overflow? Can the storage drums crack? Are the trucks in for repairs damaged and leaking? What are the potential discharge volumes?”

Asking the right questions will help in the development of a game plan for the handling of any spills that occur. First, examine what type of work is done in the shop and the frequency of each. Note common repair procedures that involve fluids. Where are fluids stored in the shop? Does the shop have dedicated bays for oil changes? Ask the team how often these jobs result in spills.

It pays to be meticulous in this evaluation and assessment process. Account for any and all fluid-related instances, and plan accordingly.

“You want to look at your total gallon and a worst-case scenario,” said Susan Naser, vice president of sales and marketing at SpillTech, a manufacturer of industrial absorbents. “Say you have 10 55-gallon drums—550 gallons. Are you really going to absorb all 550 gallons at one time? No, you’re not. But one 55-gallon [drum] might fall.”

In such a scenario, Naser advised to have 55 gallons of absorbency around just in case. “That is how you have to look at it; you have to look at your total, then you have to look at your worst-case scenario.”

She said large spills are not common, but small ones can do big damage via slips and falls. According to the National Institute for Occupational Safety and Health (NIOSH), more than one in four nonfatal work injuries that resulted in missed work in 2019 were related to slips, trips, and falls. With technicians in such high demand, shops can’t afford to have them miss time due to accidents. And due to the nature of trucks and their need of fluids and greases to work, the potential is always there.

“Greases and oils are very, very slippery—and you have a lot of people walking around,” Naser explained. “So, you need to make sure those floors are clean and dry and oil-free so that you don’t have slips and falls, which is the No. 1 worker comp[ensation] situation in most facilities. Drips lead to slips.”

Other factors to consider include the potential for flammability, corrosivity, and chemicals and fluids to enter drains. If a truck starts to leak outside of the facility, the shop should know how to address that as well.

Prepare for the inevitable

After assessing the fluid volumes and at-risk areas of the shop, prepare for addressing the potential spills. Smith explained Rush’s approach to preparing for such incidents.

“We’re going to determine containment methods; we always rely on a physical barrier first,” she said. “Ideally, things are double-walled, drums are sitting on containment pallets, and storage areas are surrounded by a berm. If physical barriers are not possible, for example, if the truck is in for repair, then spill kits and other sorbents specific to the potential fluid spills are placed strategically around the shop.”

To expedite cleanup, spill kits tailored to each specific fluid should be easy to access, and located in transfer areas and every other shop bay, she advised.

“We are diligent as far as strategically placing those spill kits around or close by any source of spill,” said Kevin Gollner, vice president of ethics and compliance and chief compliance officer at Rush. “You may have a 50-gallon drum; well, that would require a differently sized spill kit than maybe fluid leaking out of a truck right next to a service bay, or maybe a 1,300-gallon tank outside.”

When preparing a spill-reaction plan, safety is paramount. After understanding where spills may come from, prepare to safely address them.

Personal protective equipment is key, Naser explained. “If there’s any kind of spill, make sure that you have the proper protection—eye protection, hand protection—even with basic oils and greases.”

The chemical and PPE manufacturers will have the safety data sheets and literature needed to ensure the PPE can handle the spill.

Naser also emphasized being prepared for what is at risk of contamination from spilled fluids.

Federal, state, and local regulations may also call for reporting certain incidents, so shop management should be familiar with what is required and when. Otherwise, the company may be open to fines and penalties.

Picking the right spill kits and equipment

A myriad of spill cleanup and containment products, as well as equipment to handle and facilitate fluid management, are available. To select the right ones, a manager should have an idea of their spill-management needs and seek the products and equipment that will help serve them best.

The Andax Big Containment Pac, for example, includes gloves, a disposable bag, pads, socks, and an inflatable containment bag, and can contain up to 110 gallons and absorb 10 gallons total. Shops also should have plenty of degreaser to help with final cleanup of the floor, equipment, and personnel. Kafko’s Oil Eater Heavy Duty Spill Kit includes a 5-gallon bucket of its biodegradable Oil Eater Cleaner/Degreaser along with absorbent pads, pillows, universal snakes, booms, protective gloves, oil-resistant, high-temperature disposal bags, and an emergency response instruction guide.

“We rely on universal spill kits rather than a chemical-specific kit,” Smith said of Rush’s choice of kit type. “One problem our industry faces is [that there are] a variety of different fluids that have the potential to be spilled on-site. The universal spill kits can take care of a variety of fluids safely and effectively.”

Smith said Rush technicians favor durable sorbent rolls for smaller spills.

“The technician can take as little or as much as they want,” she explained. “It’s great to put down when you’re working on preventative maintenance or a repair where you know there’s going to be leaking fluid.”

SpillTech’s Universal Commander Roll, No. GRSF1550S, is one such product, which Naser said is key for vehicle maintenance personnel. “With this roll, you tear off what you need. You take it to your workstation as your own little personalized roll for use for any leaks, spills, drips, and stuff that you have.”

SpillTech also has the Roll Holder Dispenser with Magnets, No. A-MAGRACK, that further extends the versatility of the universal sorbent roll. Naser advised that technicians attach the rack to their rolling cart, or even on a vehicle lift in-bay, to allow technicians to have quick and easy access to the absorbent material.

“We’re the alternative to older methods like clay or loose absorbent,” Naser said. “Nobody wants to get a bag of dirt and throw it on an oil spill. You already have a mess. Now, you make a bigger mess.”

Furthermore, Naser explained that size and quantity of cleaning material are important aspects of the equation.

“It is all about minimizing waste, too,” Naser said. “We make a product that is an expense.”

And this waste is absorbed financially by the business and later by the environment.

“What we find is that most people don’t use the pad to its full capacity,” she continued. “You buy this heavyweight pad, you wipe down a little bit after you spill something, and you throw it away.”

Putting the right type of pad in the kit helps reduce that additional cost and trash.

Beyond spill cleanup and containment products, look for equipment that can lend to the mitigation of spills in the first place.

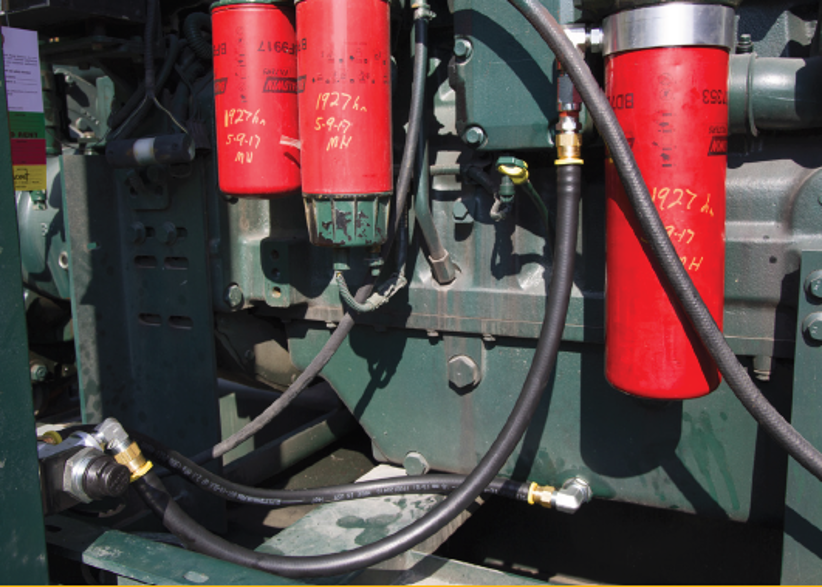

One such piece is the QuickFit Oil Change System for diesel engines from Parker Hannifin. The aftermarket system is made up of a few components and serves as a single connection point for oil changes.

“It is a flush-faced coupler that users attach to with the corresponding quick disconnect,” explained Cameron Koller, market development manager for Parker. Using the system consists of a simple three-step process. “You purge with shop air—you blow out the existing oil to the pan; then you switch to a vacuum line and, at that same connection point, evacuate the old oil; and then you return to the same connection point and refill with new oil. It’s a lot more efficient; you don’t have to mess with any plugs.”

Koller said QuickFit saves time in tight engine spaces and promotes safety.

“It gives a central point for ease of access for ergonomics,” he explained. “Every time you connect or disconnect, it is not going to spill, or have the same risk for spilling, as you typically would in a normal oil change process.”

Ancillary to the QuickFit itself, a shop would only need an air hose and a vacuum hose to utilize the system and expedite their oil changes, as well as mitigate oil spills throughout the process. Fleets can install the universal system themselves, or work with Parker’s distribution network to have it installed in their vehicles. Furthermore, the system itself does not require additional maintenance and has minimal upkeep.

“Theoretically, as long as everything’s routed and installed properly, that thing is installed and intended to not be touched until that engine has expired its life,” Koller said. He also noted that including an inspection of the system during a PM schedule is advisable to ensure there is not rust accumulation on metal components.

Shops can also leverage oil change systems. Vivek Bedi, CEO of ESOC Commercial Truck Inc., said ESOC’s closed-loop oil change systems allow technicians to change a Class 8 engine’s oil in less than 10 minutes.

“The equipment allows the operator to perform an oil change on a tractor power unit while it is hot, getting the tractor in and out of the bay at a faster time,” Bedi said. “With our system, the operator is not exposed to hot oil; the machine grabs a sample from the power unit, the system evacuates the oil [and] automatically disposes of it to a dedicated waste tank, allowing the operator to dispose of the old filters [which are dry] and reinstall the new filter without pre-filling the filters. Once the filters are installed, the machine primes the power unit to the specified volume. The engine is primed and basically [performs] a hot start; minimal metal on metal wear [is incurred] due to all the oil passages and coolers [being] filled with oil.”

Benefits include time and labor savings, an increase in safety protocols, protecting the workers from hot and hazardous fluids, and protecting the environment, Bedi noted.

“Our goal is to ‘turn downtime into road time,’” Bedi said.

Communication and training

A plan is only as valuable as its acceptance, adherence, and adoption. To execute a proper cleanup plan when the time comes, a shop must establish a culture of safety. At Rush, this starts day one for new technicians.

“We introduce the technicians to all the safety equipment on site, where it is and how to use it, and what it’s going to be used for,” Smith said. “For spills specifically, we do have the job aids and spill kits; we’re going to teach them how to avoid a spill; avoiding a spill can be the most effective way to deal with them. And then if the spill does occur, we’re going to have them evaluate the hazard.”

This entails stopping what they are doing, stopping the active spill at the source, evaluating the quantities, and securing the area. This includes eliminating any potential sources of ignitions from the area.

Next, the point person will deploy the boom, damming materials, and the sorbents found in the spill kits. Finally, they must know how to properly dispose of the sorbents in specifically marked waste bins.

“We train on this in a multitasking approach,” Gollner explained. “We prescribe, from a safety and environmental perspective, the multiple touchpoints and keep touching them over and over. We use an online learning system we call Rush University, where we send out video training to our employees. These are short microlearnings, anywhere from three to five minutes, generally. We also send the SOP out through our alerting management system. … In addition, we perform audits on our locations. … We leverage an audit as a training; we go out there, we see, and then we teach and train. We also go in every one of our locations and perform in-person ethics and safety training, we call BEST (business ethics and safety training). … We do a lot in not only spills, but safety in general at Rush.”

Creating a culture of safety will lead to the successful execution of a spill-containment plan.

“The most important part is to communicate that plan to all shop employees,” Smith emphasized. “Spill cleanup is everyone’s responsibility.”

With everyone on board, and safety in high regard, addressing spills can become an efficient practice that will keep those in the shop out of harm’s way.

“One of the things that we do is say it’s okay if you’re in the middle of a job to call timeout to clean up a spill, or call somebody to clean up the spill. Or block the spill-off,” Gollner said. “No. 1, you’ve got to have a plan. And you’ve got to empower people to execute that plan. And if you do those two things, you’re going to be much, much safer—not perfect, but much safer.”

Source: https://www.fleetmaintenance.com/