Technicians can’t be off the mark when it comes to replacing advanced driver assistance systems’ sensors and cameras after a repair job, or truck safety will suffer. Experts weigh in on what tools and techniques are needed to ensure pinpoint accuracy.

As the transportation industry continues to adopt advanced driver assistance safety systems—which include blind-spot monitoring, front collision warning, and lane-keep assist, and park assist systems—the number of cameras and sensors on commercial vehicles is increasing. Installing these measures goes a long way toward improving vehicle safety, but it is vital that fleets understand that after repair work, those sensors and cameras must be calibrated and recalibrated to ensure they are functioning correctly.

“If something is off by minuscule proportion on a camera or radar, its ability to sense what is in front of it or around it is impacted significantly,” said Tom McGuire, COO of Precision Diagnostics. “If it is trying to steer the vehicle, a millimeter or two could determine if [that vehicle] goes down the road straight or not.”

Improperly calibrated sensors and cameras, especially on heavy-duty vehicles, can have catastrophic results.

“Even if a camera is off just 0.6 degrees, that could affect the accuracy of the information being received by the safety system,” said Allison Whitney, content manager for Autel U.S. “And in the case of a collision warning or automated braking system, that might mean the vehicle doesn’t stop in time to avoid a crash.”

A lane-departure warning sensor may fail to detect another vehicle, and if the driver is depending on the system, an accident can occur, according to Brandon Alexander, marketing manager for ThinkCar.

“Improperly adjusted front sensors related to adaptive cruise control can allow the vehicle to get too close to other vehicles, making a safe ‘panic stop’ impossible,” he said. “Conversely, out-of-position sensors may result in the ADAS becoming overly sensitive and making unnecessary corrections or warnings, causing the driver to ignore or defeat the system altogether.”

“Many of us have experienced lane departure assistance in our personal vehicles where we feel the steering wheel tug while switching lanes without a turn signal,” noted Jason Hedman, product manager at Noregon, which makes the JPRO scan tool. “This feeling is greatly amplified in a commercial truck, so a misaligned lane departure system can leave a truck driver fighting the steering wheel to stay in its lane.”

Most if not all heavy-duty vehicle manufacturers offer radar and camera-based systems on new tractors and trailers. Plus, new technologies such as autonomous driving along with an increased attention toward safety will boost ADAS sensor implementation.

“The take rates continue to climb, driven by the fact that the systems do a good job of what they’re supposed to in terms of mitigating risk,” said TJ Thomas, director of marketing and customer solutions, controls, at Bendix Commercial Vehicle Systems.

“Depending on the vehicle and the equipment on the vehicle, there will be 200-plus sensors with over 20 directly related to the ADAS system such as cameras using light of various spectrums and radar systems,” Thinkcar’s Alexander added.

Inching toward standardization

ADAS on commercial vehicles are not mandated by law and are not as common as in passenger cars, so it’s still a new technology and unknown to most technicians, said Dario Peruch, managing director of TEXA USA. “However, it’s here, and it’s happening now. Getting familiar with it ahead of time will definitely help technicians and shops in the future,” he said.

The rise in ADAS and safety systems has complicated what were once routine procedures. “Traditionally, replacing a windshield meant taking out the old one and installing a new one. Today, technicians must recalibrate ADAS systems and test drive the truck to ensure everything is aligned correctly before handing the vehicle back to the customer,” Hedman said.

Several services, including bodywork, windshield replacement, tire alignment, or suspension repair, require sensor re-calibration for the vehicle to return to operation safely. ADAS sensors and systems, like any other electronic component on vehicles, require the use of scan tools to diagnose the problem, find information about the issue, and, if needed, recalibrate those systems according to the OE specs.

According to Scott McKinney, product manager for ADAS diagnostics for Bosch, there are different distance and height requirements when recalibrating sensors, and every vehicle is different. “We’re sort of in the wild, wild west right now for ADAS in that there isn’t a lot of standardization,” McKinney surmised.

He did note that the SAE and AAA have identified 20 recognized systems and five categories of systems.

“One issue with sensors is the challenge of locating them; given their size and the fact that their location can vary based on component or manufacturer, simply locating the sensor without assistance can be a difficult task,” Hedman said.

Measuring success

Precision Diagnostics utilizes tools from Autel and OEMs. “We work for one large rental organization—any work we do for them has to be done with OEM equipment. Otherwise, it is not valid in their world,” McGuire said, adding that technicians will also cross-reference the materials. “Some vehicles you can calibrate more than one way. We want to make sure our techs have the best possible information.”

A good diagnostic and calibration system scans the vehicle, alerts the technicians to the presence of an ADAS, and advises on the type of calibration needed for the device if a code is present. “Every technician needs to know that just because an ADAS system does not present a code does not mean that the device is operating to specifications. Even the most minor collision can misalign a sensor or camera,” Whitney said.

Autel’s MaxiSYS 909CV scans all the available systems and identifies the ADAS on the vehicle. Plus, it can initiate dynamic calibrations on Classes 6-8 vehicles and will soon support static calibrations on them as well, with the addition of a frame system. That includes camera calibration targets and radar calibration components.

Bosch’s guided tool walks technicians through the entire process, including pre-conditions for calibration, which could be ensuring the fuel tank is filled, removing additional cargo from the trunk, and making sure the windows and doors are closed. “We auto-ID the vehicle with a scan tool, and it comes up on screen and walks you through the requirements. It really makes it simple and easy for the technician to perform the calibration and know they are doing it correctly,” McKinney said.

Bendix developed its ACOM Pro tool in collaboration with Noregon, and it is based on the same platform as Noregon’s JPRO. The technology has wiring diagrams, which Thomas said are particularly helpful. “They give the technician the ability to understand pinouts are there, how components are connected together so they can trace down more complicated faults,” he said.

The TEXA TRUCK scan tool offers pre/post scan of all available ADAS in the market, including dynamic and static calibrations, both light- and heavy-duty vehicles. Like for other ECUs, the technician can scan the system, find DTCs related to the faulty components, and at the end of the repair, perform a new calibration. “The process is not too different from other repairs carried out in the shop. The only difference is that it’s new. Instead of replacing injectors or a VGT, the tech will have to replace a camera or radar,” Peruch said.

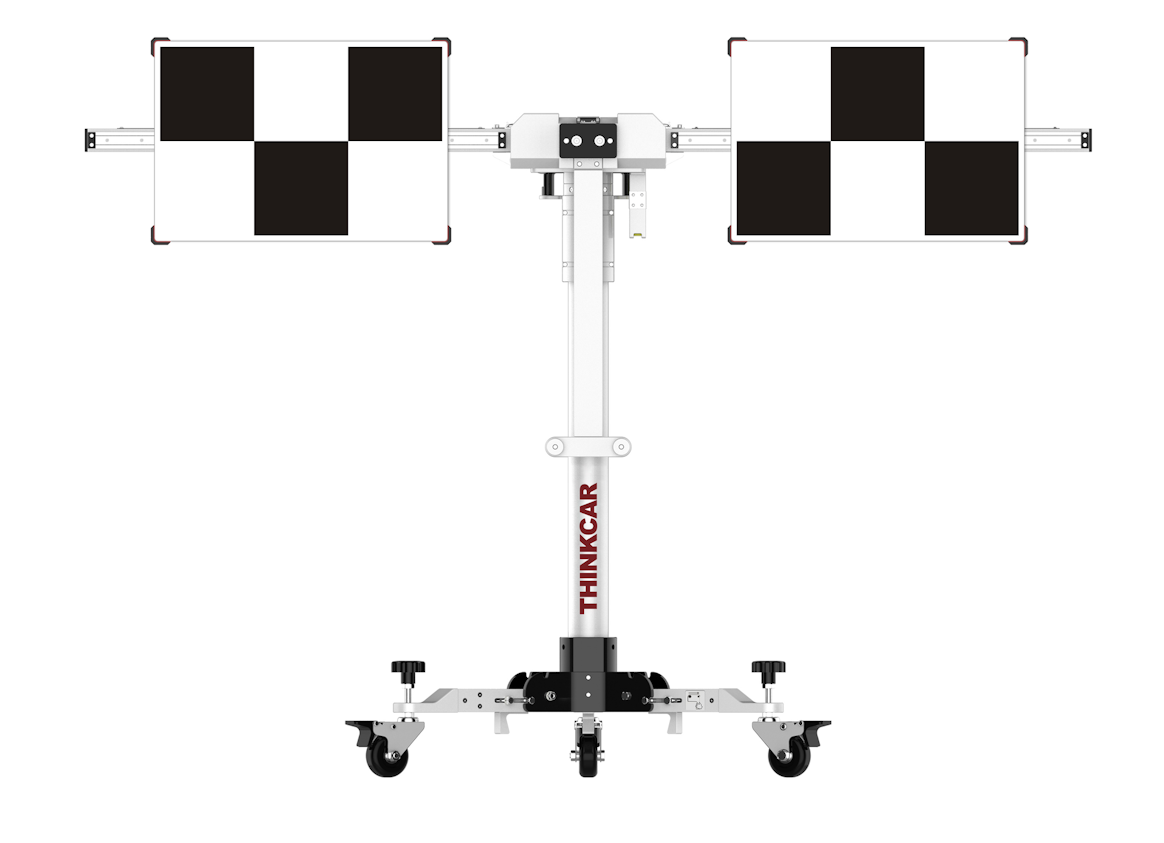

ThinkCar’s ADAS calibration equipment consists of two main components; the external hardware and the diagnostic tools used to adjust vehicle sensors. “The external hardware includes frames which are placed in very specific positions relative to the vehicle to hold targets in place,” Alexander said. “The targets look simple, but they are not, and it’s imperative the targets are exactly the correct size and shape.”

Even the environment technicians are calibrating in is hypercritical. “In our calibration centers, we are very particular about the colors we use on wall surfaces and ceiling surfaces, the type of lighting we put in, and level surfaces. It is little things like making sure tire pressure is correct when you calibrate it,” McGuire said, adding that fuel must be at a certain level. “That affects the weight, that affects the level.”

Hedman said having the ability to use a single tool to diagnose and follow troubleshooting steps to locate the cause of the error and then calibrate the system is a significant time-saver for technicians.

Ensuring long-term functionality

What’s more, not performing calibration is a serious liability for the repair facility. Whitney said good diagnostic and ADAS calibration systems provide the technician with the tools and software needed to perform the intricate ADAS calibrations as well as detailed reports documenting each step performed throughout the diagnostic, repair, and calibration process.

McGuire recommends documenting that calibrations are completed. “We’ll screenshot the calibrations, and all of the scan data is included on the final invoice,” he said. “If there ever were a liability question, we would be able to support what was done.”

Two things can occur if the calibration is not done properly—the vehicle computer system will reject the session and/or the ADAS will not function properly, Alexander said.

The No. 1 way technicians know something needs to be fixed is a DTC light on the dash. “Our systems are designed that if something isn’t working properly, they set a fault. Sometimes it happens that the driver will notice some type of performance difference,” Thomas said. “That might mean a sensor is right on the edge of calibration, and you get into a situation that is on the edge of performance. Drivers are really astute. They notice everything.”

Safety systems continue to get more and more integrated with the vehicle itself, Thomas said. “These systems are intertwined and interact,” he said, adding that when technicians start a repair, they should look for the larger scoped DTC errors first. “A lot of times, our systems are tied to other systems. If it affects their system, you should start there. There is a cascade effect.”

Thomas said it is crucial the calibration tools are updated regularly, and Bendix updates its every three to four months.

Noregon’s JPRO allows technicians to see data points in real-time across multiple ECUs. “This helps technicians discover the general area of a communication failure and use a wiggle test, multimeter, or other method to pinpoint the exact wire or sensor causing the issue,” Hedman said.

The ROI on an ADAS calibration system is a month or two even for shops just completing a handful of calibrations, McKinney said. “Being able to offer the service helps not only those customers who have ADAS, but also gives you an opportunity to talk about what else you offer,” McKinney said.

By Mindy Long

Source: https://www.fleetowner.com/