Photo: Enterprise Fleet Management

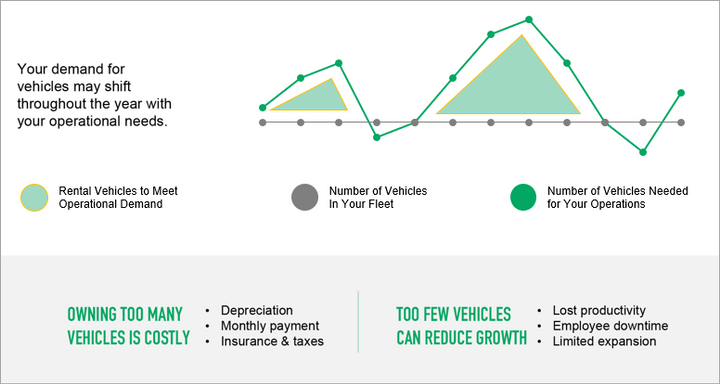

Many fleets experience a shift in vehicle needs throughout the year. Ensuring you have the right mix of available vehicles and considering rental units from high-demand can help save on overall operating costs throughout the year.

As work truck fleets balance meeting customer expectations while keeping costs in line, especially during crisis times, tracking top fleet costs becomes more important than ever.

There are dozens of fleet costs that require continual analysis, tracking, and assessment, including vehicle acquisition, fuel, preventive maintenance, and driver training.

A few costs rise to the top of the list as the most critical and essential for fleet management to plan for and monitor.

“Costs are the most visible metric a fleet has to make data-driven decisions,” said Carl Marquez, manager of data insights at Donlen Corp. “Knowing your operating costs and having metrics used to measure and monitor allows a fleet to develop actionable strategies.”

Several fleet management companies recently weighed in on the topic of work truck fleet costs and what to do about them, as well as some of the most overlooked fleet-related costs.

Here’s what our panel of experts had to say:

Cost 1: Fuel

As fuel prices fluctuate and sometimes dramatically rise, as evidenced of late, fuel is a top work truck fleet expense. So when budgeting fleet expenses, this is a critically important factor to consider.

Some strategies to decrease fuel expenses include:

- Acquiring trucks with high-efficiency engines.

- Implementing telematics to reduce unnecessary idling by drivers.

- Using GPS and mapping software to determine the best routes for minimizing fuel usage.

- Participating in a fuel card program.

“You can enroll in a fuel card program to ensure that the right fuel is being used and to prevent unauthorized fuel expenses that exceed the designated amount for each truck’s operation,” said Chad Macek, national client partnership manager at Mike Albert Fleet Solutions.

According to Tim Wrinkle, construction product manager at Mack Trucks, it’s also important to invest in quality trucks that will last, including fuel-efficient components.

“This investment will pay off in the end,” he said. “An integrated powertrain will help save on fuel costs and is proven technology. Components that are integrated work better together.”

While fuel costs are substantial for lighter duty fleets, fuel costs for heavy-duty truck fleets are by far the most significant spend, often representing 60% or more of the total cost of operation, according to Marquez.

“Fuel costs today are the cost of operating that vehicle, which won’t change until alternative fuels or power sources are widely available,” he said. “Outside of alternatives, a fleet is left with ensuring they ‘spec’ a vehicle for optimal fuel economy.”

Cost 2: Maintenance

Other major costs associated with work truck fleets include operational expenses, including maintenance. These costs can take up a large part of a fleet’s budget.

“When expenses like maintenance, fuel, and repair costs aren’t addressed as part of the overall fleet strategy, it can lead to increased costs, downtime, and ultimately lost productivity,” said Dain Giesie, assistant vice president of business development at Enterprise Fleet Management.

Because fleet-related costs impact a fleet’s efficiency, it’s imperative to prioritize preventative maintenance, which can help reduce trips to the shop in the future and prevent accidents from occurring, Giesie added.

According to Marquez, maintenance costs can run anywhere from second to third as far as operational fleet costs, and is heavily dependent on the age and application of the vehicle.

“When that vehicle is not operational, it can result in lost revenue or in another expense in acquiring a rental,” he added, explaining that a vehicle that is working eight-plus hours a day in the varying road or off-road conditions will need more care. “Understanding this and changing your mindset to treat your work truck fleet differently is key to success.”

According to Macek, preventive maintenance is critical to a healthy fleet and should be monitored closely by fleet leadership. Following maintenance schedules is imperative to ensuring vehicle warranties aren’t voided.

Plus, each truck’s life cycle is relative to its maintenance requirements, as the higher the miles, the more maintenance costs will increase.

“If you hang on to your trucks too long, predictable preventive maintenance turns into unpredictable, excessive expenses, such as transmission or engine replacements and other high-priced repairs that can seriously hurt your bottom line and productivity,” Macek added. “We always suggest cycling out your trucks before they start costing you more than they’re worth.”

Cost 3: Acquisition & Upfitting

Vehicle purchasing costs and aftermarket additions remain a major cost for truck fleets and can run especially high depending on the application. Having a thorough understanding of new vehicle specs and capabilities and utilization across the fleet can result in cost-saving opportunities when it’s time for vehicle acquisition and upfitting decisions.

Factors to be considered when acquiring vehicles include defining ways to upfit your trucks with the best equipment that maximizes driver safety and productivity, keeping in mind the job at hand, and selecting trucks with the optimal capacity to handle specific on-the-job needs.

“Trucks that are too small will likely result in higher maintenance needs and other serious issues that lead to shorter life spans and the need for more frequent replacements,” Macek said. “Trucks that are too large may unnecessarily increase acquisition costs and fuel consumption. It’s important to have the right size trucks to avoid long-term ramifications.”

Macek offers these tips for cost-effective vehicle acquisition planning:

- Order trucks from the manufacturer through a fleet management provider instead of buying them at marked-up prices from retailers.

- Be mindful of manufacturers’ production schedules and place orders well in advance to ensure delivery of your trucks when you need them.

- Set up a manufacturer discount program when possible (a fleet management provider can help with this).

Having the right amount of suitable vehicles in a fleet can improve efficiencies and lower overall total cost of ownership, according to Giesie, who stressed that these costs impact companies that operate work truck fleets in two ways: through competitiveness and availability.

“This can also be described as optimal fleet utilization, which is the number one way of optimizing and measuring fleet efficiency,” he said. “Similar to proper staffing, fleets need to make sure they have enough available vehicles to capture new market opportunities, but they also must ensure they don’t have too many vehicles that are sitting in idle and creating unnecessarily high costs.”

Finding the right balance allows companies to remain competitive in their market, which is where having the right amount of the right types of vehicles to meet business demand comes into play.

And, as Giesie points out, this may also include getting vehicles to supplement additional transportation needs during peak times of the year.

“Following this approach, fleets can keep costs in line and maximize time that vehicles spend on the road,” he said.

To also keep upfitting costs from skyrocketing, talking with your drivers about daily vehicle use can help pinpoint the most valuable equipment add-on solutions, according to Macek.

“Whether that requires tool boxes, service bodies, ladder racks, a custom engineered solution, etc., upfitting your trucks accurately can be a game changer in terms of protecting your team and assets and making it faster and easier for your team to complete their work,” he said.

Factoring in upfitting time into your truck delivery schedule from the get-go is also important when you’re planning your acquisition strategy. This is especially critical during times that cause labor challenges or auto part shortages, such as those caused by the recent pandemic, Macek advised.

Marquez echoed this advice, urging fleets to put vehicle specification and upfitting needs toward the top of the cost analysis list.

“With the large trucks such as Class 8, optimal specifications will work to reduce fuel spend, maintenance spend, and downtime,” he said. “Upfit repair tends to get bundled with any of the top costs (mostly maintenance), hiding any association with increases in top costs.”

Other Top Costs/Commonly Overlooked Costs

The three categories of top work truck fleet costs discussed above is only the starting point, according to our fleet management company experts. Other top work truck fleet costs that fall at the top of the list include:

- Insurance.

- Driver wages and benefits.

- Accidents and injuries.

- Overhead or indirect costs.

Plus, the panel advised to make sure these commonly overlooked fleet costs don’t fall through the cracks:

- Depreciation.

- Engine idle time.

- Driver turnover.

- Timely vehicle cycling.

- Permits and compliance.

- Downtime.

CUT COTS OF THE FLEET WITH OUR AUDIT PROGRAM

The audit is a key tool to know the overall status and provide the analysis, the assessment, the advice, the suggestions and the actions to take in order to cut costs and increase the efficiency and efficacy of the fleet. We propose the following fleet management audit.