Reliability-centered maintenance goes beyond preventive maintenance by analyzing and prioritizing the causes of vehicle failure, helping fleets identify solutions that improve uptime while minimizing costs.

While its origins are in the aviation industry, reliability-centered maintenance (RCM) is applicable in virtually any organization tasked with managing and maintaining vehicles, equipment, and other assets. With RCM, asset reliability is the focus. Preventive maintenance plays a big role in that, but RCM takes things a few steps further.

“RCM is a structured process that identifies specific problems leading to a decrease in asset … productivity,” says Bryan Christiansen, founder and CEO of Limble CMMS, a computerized maintenance management software (CMMS) mobile app. “RCM allows teams to put in place processes that head off these problems.”

John Davis, principal fleet management consultant for Dossier Systems, says the increasingly devastating impact of downtime is encouraging more fleets to look into RCM.

“Today’s driver shortage is putting even more pressure on fleets to keep cargo moving,” Davis says. “That comes down to one thing: reliability.”

Dossier Systems is a provider of fleet management and maintenance software.

Along with improved uptime, a primary goal of RCM is reduced operating cost.

“A better-maintained vehicle typically operates more efficiently and consumes less fuel and oil,” Christiansen says.

Additionally, RCM helps lower maintenance and repair costs because preventive-type work is typically less expensive than emergency repair work. A well-maintained vehicle also operates more smoothly and suffers less wear and tear, potentially resulting in fewer major repairs and longer component life.

“There is also more of a spirit behind the maintenance effort because a real purpose has been defined: increase asset reliability,” Christiansen adds. “Fleets begin to track failures [breakdowns] and analyze the root cause of those failures. That allows fleets to put actionable plans in place to prevent future failures.”

How fleets can implement RCM

Since RCM involves a very thorough, structured process, it can also be time-consuming. Sometimes, some of the elements of RCM don’t even apply to fleets. However, the core philosophy makes a lot of sense. With the right implementation, RCM can become a valuable tool for fleets.

Nonetheless, fleets should be cautious in their pursuit of RCM.

“Some people really love initials because initials make something sound really important,” says Joel Levitt, president of Springfield Resources, a management consulting firm specializing in the training of maintenance leaders. “A lot of times, people don’t understand the real meaning behind those initials. In the case of RCM, some people think it’s simply about good maintenance. But RCM is a lot more than that.”

To that point, Levitt says formal RCM has little or no place in a fleet maintenance operation. That is because RCM states that if a failure results in loss of life or environmental catastrophe, the company (i.e. fleet) has an obligation to redesign the system to virtually eliminate the possibility of another failure.

“Not too many fleets have control over the engineering of their trucks and trailers,” Levitt says.

What fleets can do is document their failures and offer feedback to manufacturers to help the OEMs bring safer and more reliable equipment to market. But when it comes to RCM, the most practical point of application for a fleet has to do with predictive analytics: studying past failures to determine causes, trends, and warning signs.

The Society of Automotive Engineers developed SAE JA1011 as its standard on RCM in 1999. SAE JA1011 presents seven questions that can help fleets develop the necessary policies to better manage failures:

- What are the functions of the asset (i.e. truck or trailer) and desired standards of performance?

- How can the asset fail?

- What causes each failure mode?

- What happens when a failure occurs?

- What are the consequences of a failure?

- What can be done to predict and prevent failure?

- What should be done if a suitable predictive/preventive task can’t be found in order to minimize the effects of a failure?

“RCM helps determine which maintenance [items] to do and which not to do,” says JC Leverette, chief operating officer of Andromeda Systems, a technical services organization that specializes in RCM analysis. “Many times, fleets follow the OEMs’ recommended intervals, which are based on either average or ‘worst-case scenario’ situations. But that doesn’t allow for any adjustments for things like application or operating environment.” Leverette is also chair of the SAE G-11 Maintainability Committee and is one of the original authors of the SAE JA1011 and JA1012 RCM standards.

Since RCM seeks to mitigate the consequences of failure while also minimizing maintenance costs, it is in a fleet’s best interest to make preventive maintenance decisions based on its specific situation. Fleets need historical data along with what Leverette refers to as a rigorous application of common sense.

“Take brakes, for example,” Leverette says. “On open-highway driving where there isn’t much traffic, brakes will last a long time.”

In this case, a fleet might not want to blindly follow an OEM-recommended service interval. Rather, the fleet should rely heavily on its own inspections and historical data to determine when brakes need to be serviced.

According to Levitt of Springfield Resources, fleet maintenance professionals spend a lot of time trying to avoid breakdowns.

“We don’t spend enough time on the consequences of failure,” he says. “If we did, we could find new ways a failure could be dealt with.”

For example, a delivery truck running out of fuel is catastrophic. A fleet can put policies and procedures in place to help prevent this from happening.

“In other instances, a fleet might want to invest some money and install an extra-large saddle tank,” Levitt says. “That is an RCM approach. RCM opens the door to many possible solutions that go beyond just preventive maintenance and the other routine things a fleet often does.”

Another example has to do with tires. As Levitt points out, every fleet has some degree of tire issues. When doing urban pickup and delivery, wear and tear on sidewalls is common.

“A tire with stronger sidewalls might eliminate 50 percent of this problem,” Levitt says, adding that it doesn’t require hundreds of hours of analysis to figure that out. “Just think about the problems your fleet typically runs into.”

“Questions need to be run through a logic process in order to steer the fleet toward a logical answer,” adds Leverette of Andromeda Systems. “If you know something is a problem, run it through the logic process. For example, if you have a part that is failing a lot, an RCM-based solution could be that the part needs to be inspected more frequently, or maybe you need to change to a different, better part.”

The RCM process can help fleets make those determinations. Depending on the size of the organization, Leverette says the process could involve anyone whose primary concern is asset maintenance and reliability.

When first looking to implement RCM, a fleet manager should have a discussion with management to get approval. Then, it’s important to talk with the rest of the team – including technicians, external service partners, and vendors – to explain what the fleet is trying to accomplish and what the benefits are.

Involving drivers in the RCM process is generally considered optional but might prove to be a good idea.

“With today’s driver shortage, good trucks, and maintenance practices … listening to drivers can go a long way,” Dossier Systems’ Davis says. “Drivers want to know that their employer cares about them and will listen to what they have to say. If a driver feels unappreciated, the chance of them going somewhere else increases. Furthermore, drivers will stop reporting potential issues when they see them. That is not good for reliability.”

“One of the most important things about RCM is that it helps build a ‘learning maintenance operation,’” says Ric Bedard, founder of Cetaris, a provider of CMMS software. “A good RCM process leads to continuous improvement.”

Where preventive and predictive intersect

As pointed out, preventive maintenance is a cornerstone of an overall RCM strategy. The predictive maintenance component is what can help take reliability to another level.

For example, preventive maintenance inspections might detect that the alternator on a truck isn’t generating enough amperage. Drivers have also reported squealing sounds. In looking at other trucks across the fleet, the fleet manager identifies several alternator failures around a certain number of miles. The truck in question is approaching that same number of miles. Steps can be taken to replace the alternator before a failure occurs.

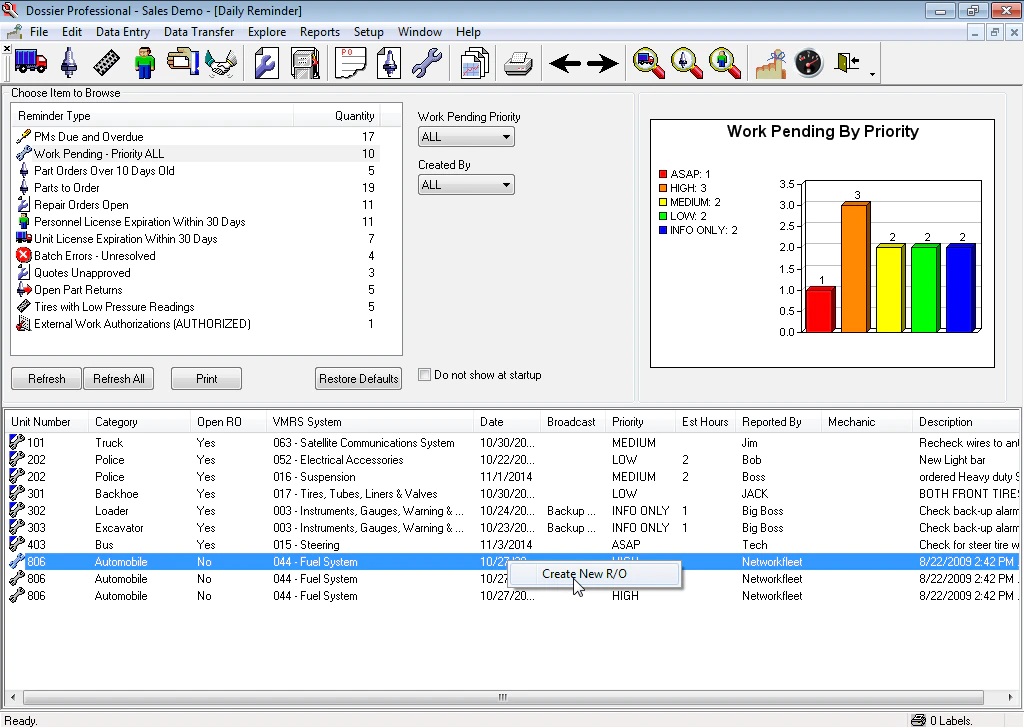

Maintenance software can help with that type of predictive analysis. Software can also help with preventive maintenance scheduling that is based on typical failure points, which helps fleets stay on top of when components may need to be replaced.

In order to perform the level of root cause failure analysis (RCFA) RCM recommends, fleets often need some degree of help from technology. Fleets need a way to quickly and accurately glean information from its trucks and trailers and then organize, prioritize, and analyze the data. According to Bedard of Cetaris, this is where some CMMS platforms fall short.

“Fleets need more than just a superficial service record,” Bedard says. “Fleets need software with a rigorous reporting engine so they can determine which assets get fixed and when, based on the level of risk they have for failure.”

Much of that data originates from the truck’s engine and other components. Numerous telematics companies provide hardware devices that plug into the diagnostic port beneath a vehicle’s dashboard (OBD-II on light duty vehicles, J1939 most often on heavy duty vehicles). The hardware device pulls data from the engine and other vehicle components and sends it to a software system (CMMS) so fleets can read it. Thus, it’s important for fleets to make sure there is seamless integration between the telematics device and software.

Fleets can quickly become overwhelmed with data, though.

“Picking out what is important is the essence of RCM,” Bedard says.

Fleets want to focus on areas where they have seen failures before, along with those items that can lead to failures with the biggest consequences.

For example, a 100-vehicle fleet suffered 15 breakdowns last year. Fleets can look at the vehicles’ engine and sensor data to see what was going on at the time of a breakdown.

“Perhaps a certain component failure is regularly occurring,” Limble’s Christiansen says. “The fleet could take steps to implement the necessary SOP [standard operating procedure] to ensure that preventive maintenance is being handled correctly, whether that’s proper oil and filter changes, pre-trip inspections, et cetera.”

Software can help fleets track those service intervals, and even alert them when a recommended service is coming due.

“A good piece of software can track unlimited maintenance schedules and intervals for different types of vehicles, as well as their components,” Dossier Systems’ Davis says. “With our system, for instance, we know that a specific component was changed on a certain date and at a certain mileage. The software can forecast when the component needs to be changed again based on that vehicle’s utilization.”

A fleet could try to maintain those records with pen and paper, relying on meter readings to determine when maintenance should be done. It’s not going to be easy, though. In fact, it might be impractical for any sizable fleet.

That is why daily dashboards are a useful feature of maintenance software. Dashboards alert fleets to maintenance and inspections that are due, overdue, or pending. Fleets can also be alerted to vehicle permitting issues and driver issues such as licensing or certifications, all of which can take a vehicle out of commission and hinder reliability.

Inventory management also drives reliability

Since RCM seeks to maximize uptime, minimizing inevitable downtime should be another focus of a fleet. To that end, strong inventory management is essential. A CMMS can help here too.

“A good maintenance software system can help determine stocking levels,” Dossier Systems’ Davis says. Those levels are really up to an individual fleet and should be based on how fast their vendors can supply them and how fast they can turn their inventory. Regardless, once the inventory minimum and maximum levels are established for each part, the software can help the fleet stay on top of things.

“Daily dashboards can help here, too,” Davis points out. “Fleets can be alerted when a certain part needs to be reordered because it reached its minimum level. The software will also say how many [parts] need to be reordered to bring it back up to the maximum level. With a good software system, all of this data is updated in real-time. A good system will also help the fleet identify slow-moving or obsolete parts so they can reconsider how many they stock, or if they even stock them at all.”

Lean, fast-turning parts inventory helps fleets reduce cost, which is a cornerstone of RCM. The other cornerstone is reliability and vehicle uptime, which is the primary goal of any fleet.

“Fleets should already be doing core RCM,” Springfield Resources’ Levitt says. “Don’t just fix the same things over and over; get to the root cause of those failures. Think about what could happen to one of your trucks and what the consequences are. Beyond preventive maintenance, is there a different solution to preventing the failure, such as a different procedure?”

It is that preventive, predictive, and solution-based focus that can make RCM a valuable tool for fleets.

Source: https://www.fleetmaintenance.com

CUT COTS OF THE FLEET WITH OUR AUDIT PROGRAM

The audit is a key tool to know the overall status and provide the analysis, the assessment, the advice, the suggestions and the actions to take in order to cut costs and increase the efficiency and efficacy of the fleet. We propose the following fleet management audit.