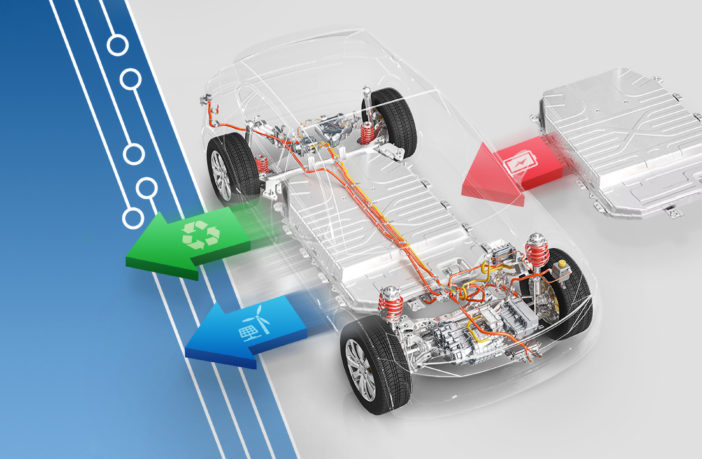

The issue of recycling of old electric vehicle batteries is increasingly more pressing as more EVs are on the roads than ever. With increased operating times an EV’s lithium-ion battery becomes less effective and needs to be replaced in the vehicle. The old batteries then begin a second life or are finally recycled and completely discharged.

In response to demand driven by the rapidly expanding electrical vehicle market, EA Elektro-Automatik has developed a range of products for the entire spectrum of battery recycling – from battery production, testing/recharge to second life to final recycling.

Its bidirectional power supply EA-PSB 10000 and regenerative electronic load EA-ELR 10000 provide safe and sustainable preparation of discarded batteries – with 96% regeneration efficiency.

If the storage capacity of the lithium-ion battery systems is no longer sufficient for use in e-vehicles, residual capacities may well be available for second-life use as energy storage for solar power or wind energy. With the EA-PSB 10000 bidirectional power supply, the batteries are tested for their remaining capacity by charging them to almost 100% and then discharging them again.

At 30kW in a 4U package, the EA-PSB 10000 bidirectional power supply EA claims it offers the highest power density on the market. Up to 1.92 MW is possible in a rack system, which means that mass testing is also possible. In addition, EA-PSB 10000 can switch between operation as source and sink.

The true autoranging capability of the PSB 10000 offers maximum charge and complete discharge of the batteries through the high load currents even at voltages below 2 volts.

After a certain operating time, batteries can only be finally recycled. For this purpose, they are disassembled into their individual parts, which can be further used. This process must be managed properly to ensure safety and prevent ignition. Lithium-ion batteries and lithium-ion polymer batteries must be completely discharged, which can be achieved with the EA-ELR 10000 regenerative electronic load – the most efficient technology on the market.

With 30 kW in 4U, the EA-ELR 10000 series, like the EA-PSB 10000 series, can achieve up to 1.92 MW in rack systems. Users can extract large amounts of residual charge from batteries in a short time and feed it back into the grid with an efficiency of up to 96%. In this way, grid regeneration reduces operating costs, protects the environment and also lowers heat generation, which usually makes expensive external cooling systems unnecessary. Optionally, the EA-ELR 10000 is available in a sealed enclosure design with 90% efficiency water cooling.

By Web Team

Source: https://www.electrichybridvehicletechnology.com

CUT COTS OF THE FLEET WITH OUR AUDIT PROGRAM

The audit is a key tool to know the overall status and provide the analysis, the assessment, the advice, the suggestions and the actions to take in order to cut costs and increase the efficiency and efficacy of the fleet. We propose the following fleet management audit.