Photos: Jim Park

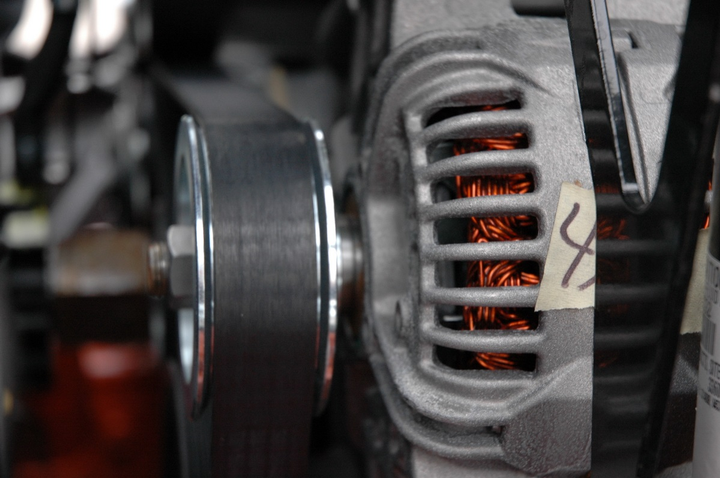

In a 48-volt electrical system, the alternator could be made smaller with the same output, or it could disappear entirely to be integrated into starter/generator and perhaps built into the transmission.

Vehicle electrical engineers are like kids in a sandbox these days. The transition to 48-volt vehicle architecture represents nearly endless potential for improvement in efficiency and functionality of electrical components. It’s almost like starting from scratch — in more ways than one.

Less than a year ago, Craig Jacobs, Eaton’s director of engineering and program management for controls & protection, transportation, military and aerospace division had this to say about transitioning from the current 12-volt architecture to either 24- or 48-volt:

“I don’t think the industry has converged on 24 or 48 volts at this point. There are a couple of different camps on this. The 24-volt supporters point to Europe where 24-volt systems are used, so there’s already some standardization, and components are readily available. The 48-volt camp says if we’re going to make a change, let’s go all the way.”

Jacobs also noted that 24-volt systems might take us out 10 or 15 years, but then we’d be up against a wall again, with limited potential for expansion. “Going right to 48 volts would last long longer before we’d see the need to upgrade again,” he said. “It also gives OEMs a lot more flexibility in how they design vehicles.”

This year’s annual meeting of the ATA’s Technology & Maintenance Council featured a panel discussion of the S.1 Electrical Study Group, examining the advantages and challenges of converting to 48-volt vehicle systems from 12. The lists are long on both sides of the ledger.

How 48 Volts Could Change Truck Design

Jim Bevan, manager of eMobility Engineering at Daimler Trucks North America said switching to 48 volts opens all kinds of doors that we currently consider impractical or unfeasible, such as a full beltless engine.

“With 48 volts, we simply have more power that we can do more things with,” he said. “When you start taking the auxiliaries off the engine, you could potentially put them in a full variable mode so they can be always in their efficiency sweet spot where you get the least amount of losses. We’ve had 12-volt systems on trucks for so long that we’ve gotten comfortable with what that configuration can accomplish. But if you start talking about 48-volt, and you have more power, more power capability, you can start looking at really feasibly electrifying different systems — air conditioning for example.”

Upping the system voltage from 12 volts to 48 volts will enable all sorts of new on-board capabilities. Among the more obvious are the many engine components and systems that could be driven electrically rather than with a belt tethered to the engine, such as air compressors, cooling fans, oil and water pumps, etc. In addition to the efficiency gains Bevan mentioned, off-boarding such components would eliminate the need to position them near the front of the engine for gear-train access.

As Jacobs pointed out, “If you take a lot of that stuff away from the front of the engine, it would give the OEMs a lot of freedom they never had before to redesign the front of the truck.”

Bevan also spoke of the potential for mild hybridization of certain drive systems on heavy trucks, similar to the systems offered by Hyliion at present.

“By rethinking certain components, such as the starter, alternator and transmission, integration possibilities open up where, for example, the alternator and starter could become the same device and be built into the transmission,” he said. “It could also be like an entire flywheel housing that’s replaced with an electric motor/generator that could add assistive power to the drivetrain on demand or reduce the load on the alternator by recouping energy from vehicle momentum while coasting, rolling downhill or braking.”

Corrosion will be a problem with 48-volt electrical systems. While voltage increases by a factor of four, corrosion could increase by a factor of 10.

12-Volt is Here to Stay

But there are some practical hurdles to all this creative engineering — the basic vehicle electrical system. Obviously, the basic in-cab electrical architecture and the trailer-trailer interface will need to stay at 12 volts, but Jeff Williams, senior power electronics engineer at Volvo Trucks says the industry has identified six other interface points on the truck where multiple voltages will need to be considered, including the battery/charging system access and the body-builder interface.

“Trailers vastly outnumber power units in this country, and they also have a longer lifespan,” says Williams. “The J-560 connector has served the industry well for over 60 years, even when ABS was added to it. I see us needing to support 12 volts essentially forever; this will not be a step event or a cliff event where all of a sudden we’re immediately at multi-voltage and 12-volt vehicle case production. We will have to support 12-volt trailers and body-upfits for the foreseeable future.”

At this stage, 24-volt starting and charging systems are common in Europe and fairy easily integrated into a modern vehicle with 48-volt architecture. Williams spoke of several devices that will need to be incorporated to successfully step down or step up voltage as required, such as equalizers, which are really just “fancy DC to DC converters.” Such technologies eliminate the need for old and troublesome series/parallel switches when incorporating 24-volts starting and charging systems.

As for the batteries themselves, the Group 31 battery is not going away, but we’ll likely see different battery chemistries and configurations, including series connections rather than parallel to get up to 24 or 48 volts.

It remains to be seen which systems on board the truck will get to 24 volts and which will see 48, but there are a multitude of design advantages to increasing the voltage. It might seem counterintuitive to those unfamiliar with the basic principles of electricity, but thinner wire and smaller components can be used with 48 volts as opposed to 12. When you double the voltage, you reduce the current by half which allows for a thinner gauge wire. If you quadruple the voltage, you cut the current by a factor of four, etc.

For example, with thinner wire windings in starters and alternators, you can make the entire assembly physically smaller and lighter. As a result, you get the same power output from a smaller motor or additional power output if you maintain the size of the unit.

“In the case of a 24-volt starter, you can drop down to the next smaller casting size, saving room with the installation as well as some copper, steel and aluminum,” Williams says. “Or, if you keep the casting the same size but stuff it with 24-volt windings, you can get an additional few horsepower of cranking power. In most cases, motors designed for higher voltages are more electrically efficient, which in the long run saves fuel.”

All of this talk of transition begs the question, how will we standardize it all? This wouldn’t be the first time we’ve seen one or two OEMs or major suppliers head down a particular path on their own leaving fleets to deal with the inconsistencies. This time, The Society of Automotive Engineers and TMC are getting involved early to stay ahead of this rather significant change.

“SAE and TMC are already looking at this through SAE Truck and Bus Electrical Systems Committees and the S.1 task force at TMC as well as OEMs and suppliers,” said panelist, Fred Kelley, director of engineering at Prestolite Wire and chair of the SAE Truck and Bus Electrical Systems Committees. “There have been lots of discussions already and SAE recently created a Multi-voltage Taskforce to identify what was missing and recommend how to move forward.”

In December 2018, the group created a roadmap outlining the steps required to move forward and identified standards that would have to be updated, revised, left alone or created.

“We identified eight SAE standards that will have to remain 12-volt standards, including the SAE J-560 [trailer interface],” Kelley said. “This work also identified 16 current standards that will need to be reviewed and revised to ensure they satisfy 12-volt systems as well as high, multi-voltage systems. We also found that we will need as many as 10 new standards to accommodate multi-voltage systems.”

Engine-mounted and belt-driven AC compressors could disappear, replaced by electric motor driven compressors located within the HVAC unit.

Trouble in the Shop?

Trouble might not be the right word, but changes in the shop from procedures to the tools used and how parts are identified and inventoried will be profound, said panelist Bruce Purkey, founder & chief creative engineer at Purkey’s Fleet Electric.

“There are going to be some real challenges for our industry. We can do it, but is it going to be easy? No,” he said. “One of the things you’re going to have to look at is your parts inventory. Those circuit breakers, relays and fuses that you don’t even think about anymore? Well, just wait until somebody puts a 4-volt relay in a 48-volt plug. You’re going to get a “hi ho, Silver” and a cloud of smoke. Twelve-volt parts are not going to work on 48-volt systems. We’re going to have to start thinking about getting ready for this transition.”

Purkey talked about labeling and identifying parts by voltage, perhaps with color-coding or separate storage areas to avoid confusion. He talked about the need to develop and acquire the proper tools for working on higher voltage systems, pointing specifically to basic wiring repair.

“Wire repair will become critical,” he said. I’ve been told that as we go from 12 to 48 volts corrosion will worsen by a factor of 10. So, if you can’t maintain wire now, what are you going to do on a high voltage system? I still go into shops where I see technicians using those hard plastic butt connectors. How can you seal those?

“It’s going to be the little things that make a big difference, like requiring technicians to have their own crimpers and their own strippers. That’s not going to work anymore. If you want consistency in the repair process, the fleet will have to supply the proper tools and insist the technicians use them and follow procedures.”

Much will change for technicians, including the need for additional training, in things as basic as reading wiring diagrams to understanding the newer devices like equalizers and more advanced electrical system analyzers, Purkey indicated.

“We’ve had some big changes in the past. I can remember electronic controls. Everybody cried the blues but guess what: it got us the fuel economy we wanted, so we lived with it,” Purkey said. “Do you remember when we went from English to metric sized hardware? It didn’t change how we tightened the bolt did it? We just had different tools, and that’s what’s going to happen this time around.”

The migration to multi-voltage systems has already begun in the passenger car space, and heavy trucks won’t be far behind. Whether it’s mild hybridization or beltless components like air compressors and cooling fans, 48-volt motors will make it possible.

“It’s very exciting to think about what we can do if we start adding extra power and with it the extra capability,” said Bevan. “What can we do that we haven’t thought of quite yet? How can this impact and improve efficiency and design of the vehicle, the operation? How can this be integrated into fleets in terms of body builders? What systems are out there that could be electrified as well?”

It’s a whole new world full of possibilities.

by Jim Park

CUT COTS OF THE FLEET WITH OUR AUDIT PROGRAM

The audit is a key tool to know the overall status and provide the analysis, the assessment, the advice, the suggestions and the actions to take in order to cut costs and increase the efficiency and efficacy of the fleet. We propose the following fleet management audit.