Photo: TRUX

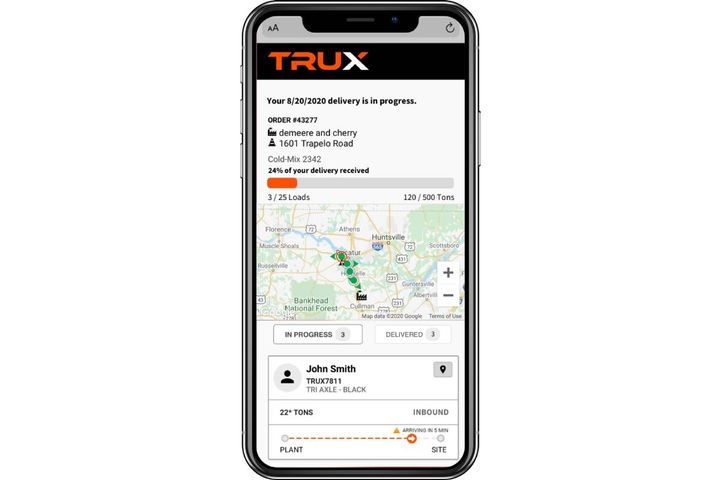

Every load delivered on TRUX is trackable by both the originator and consumer of the material.

When it comes to technology, transparency not only leads to efficiency, but also increased productivity and happier customers. Bart Ronan, CEO of TRUX, a software company that assists dump truck owners, contractors, and material producers in managing their work load and finding the work or haulers they need, discussed how technology is improving last-mile delivery in regard to the construction industry.

Facing and Solving Challenges

According to Ronan, the world of heavy construction is made up almost entirely of last-mile delivery. Common challenges he sees in last-mile originate prior to the execution of the delivery, such as finding and scheduling haulers; during the delivery with communication and tracking; and after the delivery is completed during back-office operations.

“With less than 1% of operating expenses in construction going towards technology, there hasn’t been the same investment in improving last-mile logistics that other industries, like eCommerce, have seen,” he said.

Finding the right tool that meets all the needs of diverse business lines is seen as a challenge. In addition, for those that do adopt technology, there is also a change management challenge. Getting buy-in and empowering employees to use the technology is critical to fully realize the value last-mile logistics solutions provide.

COVID-19 has certainly impacted the industry and accelerated the need for solutions that offer e-ticketing, digital collaboration, and remote work for key roles like dispatchers.

“While COVID-19 may eventually fade from the forefront of the discussion, the changes that state DOTs and construction companies are making now will certainly have staying power in 2021, 2022, and beyond,” he explained.

The logistics management functionality of the TRUX platform has allowed customers to improve their loads per hour delivered by 15% through more efficient scheduling, while also reducing their freight costs by 4%. Photo: TRUX

Using Tech to Streamline and Meet Goals

TRUX is a complete logistics platform for the heavy construction industry that supports all varieties of dump trucks. Every load delivered on TRUX is trackable by both the originator and consumer of the material. The solution provides visibility and accountability that was not previously available, allowing companies to manage the dump trucks they hire in the same way one would manage the trucks they own. This transparency helps keep teams and partners accountable while meeting ever-increasing demands of end customers for greater visibility. The tool also offers a two-sided marketplace that connects dump truck owners with local work.

Haulers get more take-home pay, and contractors and material producers see a decrease in their effective cost per hour. Photo: TRUX

Keeping Costs Under Control

Ronan estimated the total addressable market for heavy construction logistics in the U.S. is around $18 billion per year. The logistics management functionality of the TRUX platform has allowed customers to improve their loads per hour delivered by 15% through more efficient scheduling, while also reducing their freight costs by 4%. Haulers get more take-home pay, and contractors and material producers see a decrease in their effective cost per hour.

He said he is also seeing significant time-savings for roles like dispatchers, with some companies seeing as much as a 40% increase in productivity. In addition to this, the data the company is collecting is helping customers price more efficiently and schedule more effectively, among other things, all reducing waste and driving down costs.

One customer out of California, Miguel Miranda, owner of 3531 Trucking Inc., manages a fleet of more than 150 dump trucks and has been using TRUX to provide what he feels is a superior service to his customers.

“Our customers want to know what they get for their money. With TRUX, we are able to provide them transparency about where our trucks are while they are on the job. The additional layer of service and transparency TRUX allows us to provide to our customers ensures they use us again and again,” Miranda said.

Ronan said he is also seeing significant time-savings for roles like dispatchers, with some companies seeing as much as a 40% increase in productivity. Photo: TRUX

TRUX Brings the Benefits

The most common feedback Ronan receives is, “we’ve been doing it this way for a long time; why would we switch now?” This line of thinking can easily be combated when it comes to the increase in efficiency technology like this can provide, such as:

- Real-time views of material on the way to the jobsite, allowing contractors to effectively manage their crews and optimize labor and material costs.

- Enhanced communication tools that remove friction and ensure partners are working with the most up-to-date information.

- Digital tickets and load slips, ensuring compliance with increasing safety and compliance demands.

by Lexi Tucker

CUT COTS OF THE FLEET WITH OUR AUDIT PROGRAM

The audit is a key tool to know the overall status and provide the analysis, the assessment, the advice, the suggestions and the actions to take in order to cut costs and increase the efficiency and efficacy of the fleet. We propose the following fleet management audit.