Telematics has been helping fleets track, monitor and manage vehicles for many years. Now the same technology is being applied to trailers, helping fleets gain further control over their assets.

“Fleets need to know the location of a trailer, if the trailer is loaded and if the trailer is healthy,” says Gerry Mead, director of innovation for Phillips Industries, a supplier and manufacturer of parts for the commercial vehicle industry.

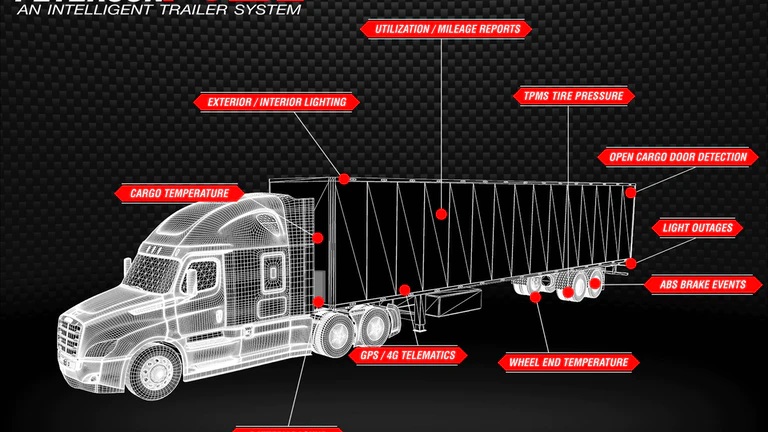

Telematics can help answer all of those questions. GPS satellites tell fleets where a trailer is. Trailer-embedded sensors offer insights into vital components such as tires, brakes and lights, as well as events such as open doors and changes in temperature.

With respect to location tracking, telematics provides a significant improvement over traditional methods.

“Most fleets rely on last-drop locations, typically documented by either the driver or a service technician,” Mead says. “If they don’t spot the trailer correctly in their transportation system, there will be some tracking issues. This can happen pretty easily when cargo is transferred from one trailer to another. If both trailers are not spotted correctly, the fleet runs the risk of losing assets.”

The dependence on people has evolved into a more streamlined process with the latest telematics technology, Mead adds.

Technology companies are making it easier for fleets to adopt trailer telematics. One example is IOSiX, a developer of fleet telematics with an emphasis on miniaturized, cost-optimized solutions. IOSiX is known for its electronic logging devices (ELDs). Later this year, the company will be unveiling a new asset tracker that lends itself well to trailer applications.

“It’s a very small device, measuring just 45mm by 130mm,” says Robert Vogt IV, CEO of IOSiX. “The idea is that it’s as simple as just sticking it on a trailer, though fleets can also bolt it on if they want to. Regardless, it will track the trailer whether it’s moving or parked. We’re targeting this as a low-cost asset tracker for roughly $2 per month, per asset.”

Vogt says this first product will provide GPS location tracking only, although the technology is there to tap into other components and wires on a trailer to provide a wide range of data. Moving forward, Vogt says additional product launches could happen relatively quickly if demand is there.

Streamlining a variety trailer data

As more fleets come to realize the benefits of trailer telematics, demand is expected to grow. Kate Rahn is vice president of BlackBerry Radar, an asset tracking solution. She says fleets can benefit from trailer telematics in the following ways:

- Improved trailer utilization

- Improved preventive maintenance

- Regulatory compliance for food, dangerous goods and emissions

- Cargo integrity through reduced insurance and customer claims

- Improved driver productivity

Like with any telematics system on a vehicle, there are four base components of a trailer telematics system:

- Tracking device that transmits location data

- Smartboard computer that connects to various sensors

- Server to store tracking and sensor data

- User interface to retrieve data

Phillips Industries’ Mead says a good user interface is essential. If accessing data is too complicated or time-consuming, a fleet will be less likely to do it. A good tracking system allows the fleet to set up dashboards, reports and alerts based on the actionable data it most desires. “Otherwise it will be like drinking from a firehose,” Mead says of the information the fleet would receive.

Phillips Connect Technologies, a division of Phillips Industries, offers the TrailerNet System, which takes sensor data from a variety of smart component suppliers and consolidates it into one user interface. This is designed to make it easier for fleets to access a variety of trailer data since they are not having to log into numerous supplier websites or apps.

Truck-Lite has also introduced a trailer telematics solution called Road Ready. Road Ready uses its own wireless sensors, which helps simplify installation. Road Ready can also access the sensors a trailer is already using. Truck-Lite has partnered with several smart component providers including Purkeys, STEMCO, Hendrickson, P.S.I. Inflation Systems and Continental to ensure that data from those smart components can also be accessed through the Road Ready user interface.

In the case of Continental, its ContiPressureCheck TPMS should be fully integrated with Road Ready sometime in 2019. ContiPressureCheck monitors tires in real-time and alerts drivers to tire pressure and temperature issues via in-cab display. Now, fleets can also get that same information through the Road Ready telematics data dashboard.

In choosing to partner with Truck-Lite, it was very important to Continental that tire data be available at all times, even while a trailer is untethered.

“We know from discussions with our fleet customers that monitoring the readiness of their trailers when parked is critical,” says Paul Williams, Continental’s executive vice president of commercial vehicle tires in the Americas. “Once this integration is complete, fleets will have access to the crucial tire data they need to reduce tire costs and breakdowns, and improve safety.”

“The Road Ready solar-powered master control unit has a 10-year rechargeable battery and can retain a charge for up to 60 days in the absence of sunlight, ensuring that there is no lapse in communication, especially while a trailer is untethered,” explains Andrew Liuzzo, a marketing communications specialist with Truck-Lite. Event-based alerting then ensures that fleets are only given the data they need through parameters set up by the fleet. Examples of alerts include when a door is opened or a tire pressure changes while sitting unattended in a yard.

Sensors: the eyes and ears of a trailer

With respect to sensors, there are numerous ways to go about placing them in different locations on a trailer. As a general rule, Mead prefers sensors to be hardwired because the flow of data is more reliable.

“With Bluetooth, for example, you’ll sometimes have a drop-off in data when there is poor connectivity,” Mead says. “You don’t get those drops when sensors are wired.”

That is why Mead suggests fleets hardwire sensors when practical with anything that ties into a trailer’s safety systems, including brakes and lights. He also prefers to hardwire when it’s a component where he’ll want to program or update that system over the air.

That said, wireless is the only way to go in some instances, such as when placing sensors on or around tires. With wireless sensors in general, companies like Truck-Lite have confidence in their reliability.

“Road Ready sensors use long-life batteries and RF [radio frequency] technology to quickly and securely communicate with the telematics master control unit,” Liuzzo says. “Because there are no wires to run or holes to drill, wireless sensors not only make for easier installation, but also preserve the integrity of a trailer.”

BlackBerry’s Radar-M device has seven built-in sensors for detecting location, mileage, door open and close events, environmental conditions such as temperature, humidity and atmospheric pressure, and cargo load sensing. Rahn says each BlackBerry Radar system is low-maintenance and easy to install, providing fleets with everything necessary to begin tracking mobile assets immediately including the device, cellular connectivity, data dashboards, mapping, hosted cloud services, etc.

Getting the Radar-M up and running requires three steps and takes minutes, according to Rahn.

“You install the external module of the device on the exterior wall of the trailer door, and the internal module on the inside of the trailer door,” Rahn explains. “Using the handy drill template that resembles the shape of the device, you drill three holes through the door and then connect the battery and secure the device using three bolts (all included). There are no wiring harnesses, brackets or external wires to run or install, which limits failure points and provides a significant cost advantage.”

BlackBerry Radar-M records sensor data in five-minute increments when the asset is in motion. Data is wirelessly transmitted to the cloud-based system in intervals designed to preserve battery life.

“Fleets can then view this data in the BlackBerry Radar portal where they have access to various data visualizations and custom reporting tools that make it easier to manage assets and improve business operations,” Rahn adds.

Improving safety system communication

Trailer safety systems are feeding a lot of the trailer telematics data. Wabco’s Intelligent Trailer Program offers several features to help mitigate potential dangers in cornering, braking and reversing. Furthermore, essential component data can be communicated through the trailer’s powerline communication (PLC) up to the truck, as well as to several third-party telematics providers.

“We get a number of requests from telematics providers to provide certain levels of data that we can draw from our ABS systems,” says Jon Morrison, Wabco’s president of the Americas. “As a leader in trailer intelligence and braking systems, we are working with many different partners and providers of vehicle information. Wabco has a unique position to generate vehicle information as well as provide essential brake system control.”

Offering its own telematics solution is something Wabco could be entertaining. Wabco in Europe owns a fleet management system company called Transics. Wabco also owns an asset tracking company in India and has a strategic partnership with a company in China. “We feel like this is an important sector to be in, and would be interested in moving into this space in North America in the near future,” Morrison says.

In the meantime, Wabco continues to focus on developing new solutions to make trailers safer than ever before. The company will be moving to a new generation of ABS system this year that is capable of providing an increasing amount of information. This new system, called iABS (“i” stands for intelligent), is a CAN bus system like that found on vehicles. The CAN bus system will allow ABS sensors on the trailer to communicate with other CAN bus sensors and systems throughout the trailer.

“One of the big challenges with truck-trailer combinations has been that trailer communication on PLC mode is different than how trucks communicate,” Morrison says. “That has made it more difficult to get a smooth transfer of information between truck and trailer. Our new iABS system addresses that. We have an opportunity moving forward to do a better job communicating truck and trailer information, which will be important as more automated functions are being implemented with truck-trailer combinations.”

Peterson Manufacturing, a manufacturer of commercial vehicle lighting and other safety products, has also focused on leveraging CAN bus technology in a trailer application. PetersonPULSE was developed in partnership with industry leaders in TPMS/ABS and telematics technology. It is engineered to CAN bus specifications using unique cabling that is lighter, more flexible and more installation-friendly than traditional harness cabling. Additionally, a backup battery provides power when the trailer is untethered.

PetersonPULSE detects real-time status of vital systems such as lights and ABS, as well as critical data including tire pressure and temperature, interior and exterior temperature, door position, GPS location and other potential condition monitoring as requested by a fleet.

“Since PetersonPULSE is an expandable, standards-based architecture, the system itself can be upgraded with minimal downtime or expense,” says Al Anderson, corporate director of heavy duty sales for Peterson Manufacturing. “Future expansion of sensors such as early warning of wheel-end issues (elevated wheel-end temperature, excessive bearing vibration, etc.) can be added as available without having to replace the trailer or rework the entire system.”

PetersonPULSE detects light-system performance through current draw monitoring with its standard LED lights. Braking activity is monitored through the braking system itself. Then, sensors for trailer tire temperature and pressure are mounted on the valve stems of each tire. Door position sensors are mounted at the bottom of the door(s) being monitored.

“Data is transmitted from the sensor to a breakout box mounted near the rear of the trailer via wired connections,” Anderson explains. “From there, the data is sent via CAN bus to a box on the front of the trailer for distribution to either a telematics device or a portable device in the cab of the tractor.”

The future of trailer safety is happening now

Technology is changing the way trailer safety systems communicate data to fleets. Technology is also changing trailer safety itself, resulting in a host of new systems and features that are making trailers safer than ever.

In addition to ABS, Wabco’s Intelligent Trailer Program includes several safety systems that interface with the braking system. One is Rollover Stability Support, which automatically applies the brakes even before the driver has realized the trailer has begun to roll over. Another is Emergency Brake Alert, which triggers flashing brake lights to warn trailing vehicles during emergency braking. SafeStart automatically brakes the trailer when a lifted dump body or an unclosed filling dome, like found on a tanker, is detected. Wabco’s Intelligent Trailer Interlock (ITI) system uses wheel speed and switch position to apply the service brakes in order to immobilize a trailer under certain conditions, such as when unloading product from a tanker. New this year is TailGuard, which detects objects in the blind spot behind the trailer, automatically stopping the trailer at a safe distance.

Also part of the Wabco Intelligent Trailer Program is TiltAlert, which warns drivers when a tipper reaches a critical tilting angle. While this system doesn’t directly interface with the braking system, it’s just another example of how vehicle suppliers are finding new and innovative ways to increase trailer safety.

Underride crash protection is an aspect of trailer safety that is getting more attention. In fact, bills have been introduced by both the U.S. Senate and House of Representatives that seek to address this issue. Both proposed laws would require the installation of rear, side and front underride guards that meet a specified performance standard on all trailers, semitrailers and single-unit trucks with a GVWR of more than 10,000 lbs.

Whether or not this proposed legislation ultimately becomes law remains to be seen; both bills were proposed more than a year ago. In the meantime, some leading trailer manufacturers are taking steps on their own.

Great Dane’s RIG30 rear impact guard is becoming standard on all of its trailer models. “We’ve been working on variations of our RIG30 for different product lines, including flatbeds, drop decks and pup trailers,” says Chris Lee, vice president of engineering for Great Dane. “Unlike other rear impact guards offered today, Great Dane’s RIG30 has a unique design that does not include outboard verticals, which can add weight and produce negative effects in aerodynamics and fuel efficiency.”

Great Dane is a trailer manufacturer, and the company is also delving into the realm of technology and telematics. Great Dane’s FleetPulse telematics system, which is currently in beta testing, uses sensors strategically placed throughout the trailer to help monitor things like tire inflation, inoperable lights, open and closed doors, cargo weight and more. FleetPulse also provides real-time alert notifications to inform drivers and fleets of issues to help enhance safety, improve uptime and prevent potential violations and fines.

Technology and safety go hand-in-hand. Phillips Industries’ Mead says it is essential that fleets put trailers on the road with side impact guards, roll stability, the right lighting system harnessing and connections, along with a sufficient telematics system that monitors the health of the trailer. All of those elements working together help make a trailer much safer.

Source: https://www.fleetmaintenance.com

CUT COTS OF THE FLEET WITH OUR AUDIT PROGRAM

The audit is a key tool to know the overall status and provide the analysis, the assessment, the advice, the suggestions and the actions to take in order to cut costs and increase the efficiency and efficacy of the fleet. We propose the following fleet management audit.

The audit is a key tool to know the overall status and provide the analysis, the assessment, the advice, the suggestions and the actions to take in order to cut costs and increase the efficiency and efficacy of the fleet. We propose the following fleet management audit.