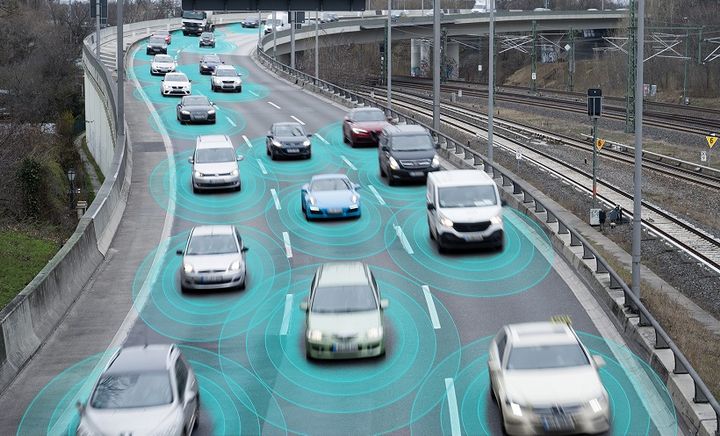

The telematics space has grown a lot since the technology’s beginnings, resulting in a variety of solutions and tools available for fleets today.

Fleet managers who are looking to support very specific fleet needs for the respective business and industry will find a lot can be gained through the utilization of telematics, whether the solutions be centered around driver safety, productivity, idling, etc.

A recent fleet technology trends report conducted by Bobit Business Media, publisher of Automotive Fleet, when looking at 2020 data found there was a reported year-over-year 8% increase in the number of fleets using telematics. This represented a jump from 64% in 2019 to 72% in 2020.

This survey featured respondents from the transportation, service, and construction industries.

Overall, these participants observed increased improvements in critical areas such as productivity, routing, and customer service, when compared to the previous year.

When breaking down other specific gains through the implementation of telematics, respondents reported an average 8% decrease in fuel costs, an 11% reduction in accident costs, and a 10% decrease in labor costs.

The survey also found that in-cab video telematics solutions had also increased in utilization for business operations resulting in subsequent operational benefits; for example fleets in the service industry using in-cab video say driver safety improved by 82%, year-over-year.

However, with the implementation of telematics devices come associated costs, a major pain point for many fleets. The 2021 survey found that 44% of fleets rated increasing costs as a top challenge to their operations.

However, the return on investment (ROI) that is brought about via the usage of telematics technologies can cancel out some of the costs associated from utilization. The survey found that 32% of respondents reported a positive ROI in six months of implementing this kind of fleet tech.

Yogi Shivdasani, VP, North America supply chain, LKQ Corporation, noted the positive ROI benefits that can ultimately be discovered for fleets, observing this in his own operations.

Shivdasani, who was the winner of the 2020 Fleet Executive of the Year award, said by implementing telematics he was ultimately able to reduce idling across his fleet, bringing the average down to 15-20 minutes.

This timeframe was closely monitored by his fleet team to make sure drivers did not exceed limits.

“If anybody’s ever thinking about implementing telematics, just look at your idling. If it’s anything over an hour, and you cut it to 30 minutes, or if it’s over an hour and a half, and you cut it to 30 minutes or less, you’ll make up for the expense that pays for the telematics,” Shivdasani said. “But there is also so much more I get out of telematics.” This ultimately resulted in a savings of $7.5 million for his fleet.

Success with this initiative was grounded in establishing a telematics program for a fleet of approximately 5,300 LKQ vehicles.

The 2021 study also found approximately 55% of survey respondents reporting the impact of the COVID-19 pandemic as having a negative effect on their operations.

Following the declaration that COVID-19 was a pandemic, the U.S. economy was divided into essential and non-essential businesses.

Many of the fleet vehicles operated by non-essential businesses were idled and parked during most of the economic shutdown. Company drivers at non-essential companies were encouraged by their management to conduct their business virtually.

Alex May, senior manager of fleet at Rollins, Inc., who manages a fleet of 13,100 vehicles that served as an essential business through the pandemic, said that telematics offered critical assistance for his fleet with regards to helping identify vehicle utilization, particularly since the downturn in the economy caused some additional employee turnover and subsequent un-utilized vehicles

“Telematics helped bring more attention to underutilized vehicles that possibly are not needed, or ones that we can transfer to other branches where they can be better utilized. We can also look at over utilized vehicles, so we can move vehicles to shorter routes to insure out vehicles last through our cycles” said May.

Marca Brown, manager – fleet optimization, DTE Energy, and a 2020 Fleet Visionary of the Year Honoree, also observed complications her fleet experienced as a result of COVID-19.

“The pandemic hit at a bad time for us. We had just embarked on what is likely the most aggressive redesign of all of our fleet processes in the company’s long history. During 2020, we created or re-designed over 40 key processes. We organized all of that effort to match DTE’s Service Keys – safe, caring, dependable, efficient,” said Brown.

Her team’s new strategy for 2021 includes continued investment in telematics solutions and other forward-looking fleet tech. “For 2021, we have created an equally aggressive plan. Among the most impactful of those will be our electrification (EV) project, customer satisfaction project, and vendor management project.”

by Andy Lundin

Source: https://www.automotive-fleet.com

CUT COTS OF THE FLEET WITH OUR AUDIT PROGRAM

The audit is a key tool to know the overall status and provide the analysis, the assessment, the advice, the suggestions and the actions to take in order to cut costs and increase the efficiency and efficacy of the fleet. We propose the following fleet management audit.