NACFE spent a decent amount of time in 2020 doing work on emerging technologies specifically commercial electric vehicles and autonomous trucking. However, we did not take our eye off diesel-powered vehicles.

I’ve had some time over the last few weeks to just think about things. And while I contemplated a fair of amount of non-trucking stuff, I also thought a lot about the trucking industry. It is no secret that I am a truck nerd and a freight efficiency junkie, so spending my off time thinking about efficiency should not come as a surprise to anyone.

NACFE spent a decent amount of time in 2020 doing work on emerging technologies specifically commercial electric vehicles and autonomous trucking. Clearly, those are the technologies of the future and that future might be closer than many of us realize.

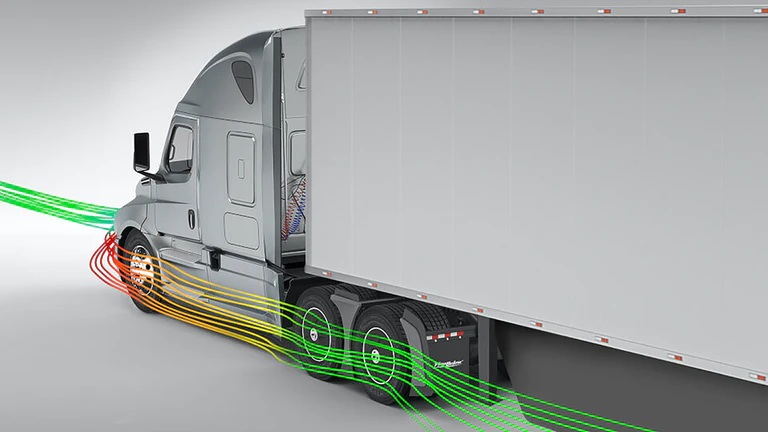

However, we did not take our eye off diesel-powered vehicles. In fact, we updated Confidence Reports on low rolling resistance tires, tire pressure systems, tractor aerodynamics and trailer aerodynamics. Throughout the years we have showcased some of the best-of-the-best fleets when it comes to getting the most miles from a gallon — or liter — of diesel.

Run on Less 2017 demonstrated that 10 MPG was achievable on a regular basis in long-haul operations and with Run on Less Regional we saw that 8.3 MPG was realistic. Both those numbers are well above the average for most fleets. There is still a lot of work to be done to help all fleets be as efficient as they can be while still being profitable.

During the last few years, we’ve seen diesel fuel prices at relatively low levels which has caused some fleets to take their eye off the fuel efficiency ball. However, fuel still accounts for nearly one-quarter of a fleet’s average marginal costs, according to the American Transportation Research Institute. Only drivers’ wages account for a larger percent of a fleet’s cost of operation.

What that says to me is that efficiency matters and improving efficiency is something every fleet should be concerned about and should work to improve. I am not naïve enough to think that every fleet can invest in every device that improves efficiency. In fact, that is not even possible. But I would hazard a guess and say that many fleets can take some step — invest in a new technology or change an operational practice — that will lead to an efficiency gain.

I will be so bold as to say that even as we work through the messy middle to what we at NACFE think will be an all-electric future, I think improving efficiency is going to continue to be important. After all, isn’t that part of the reason we keep looking for new ways to power vehicles? I understand that there are other forces at work like reducing emissions and reduce the carbon footprint of trucking, but I think those are all part of the improving efficiency equation. I would like to think that years from now NACFE will still be helping fleets improve their efficiency even after we’ve made the move to electric power for commercial vehicles.

More to come in a future blog on how efficiency helps the range of electric trucks, one of the most important challenges to adoption.

Michael Roeth has worked in the commercial vehicle industry for nearly 30 years, most recently as executive director of the North American Council for Freight Efficiency (NACFE). He currently serves on the second National Academy of Sciences Committee on Technologies and Approaches for Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles and has held various positions in engineering, quality, sales and plant management with Navistar and Behr/Cummins.

CUT COTS OF THE FLEET WITH OUR AUDIT PROGRAM

The audit is a key tool to know the overall status and provide the analysis, the assessment, the advice, the suggestions and the actions to take in order to cut costs and increase the efficiency and efficacy of the fleet. We propose the following fleet management audit.