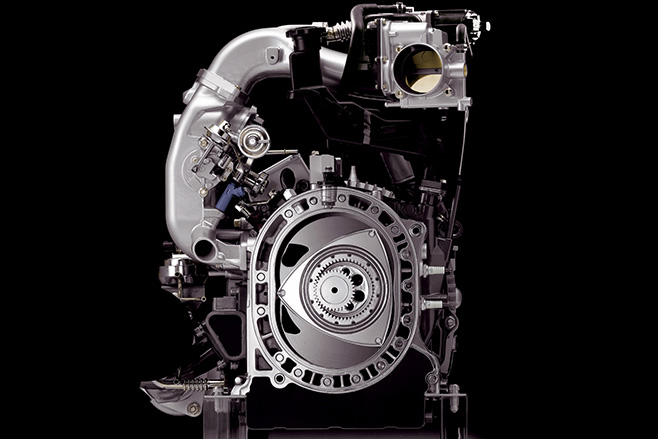

Like more conventional petrol engines, a rotary engine uses fuel ignited by a spark to produce power but, beyond that, it differs from a conventional car engine in many ways; most notably, how it takes the expanding gasses and heat of combustion and turns it into movement to push your car along.How does a rotary engine work?

In a normal engine, combustion acts on a set of pistons which produces a linear movement inside the engine’s cylinders. The pistons go up and downlike the legs of a push-bike rider and they are attached to the crankshaft, which is the component that converts that up and down motion to the circular motion that drives the wheels.

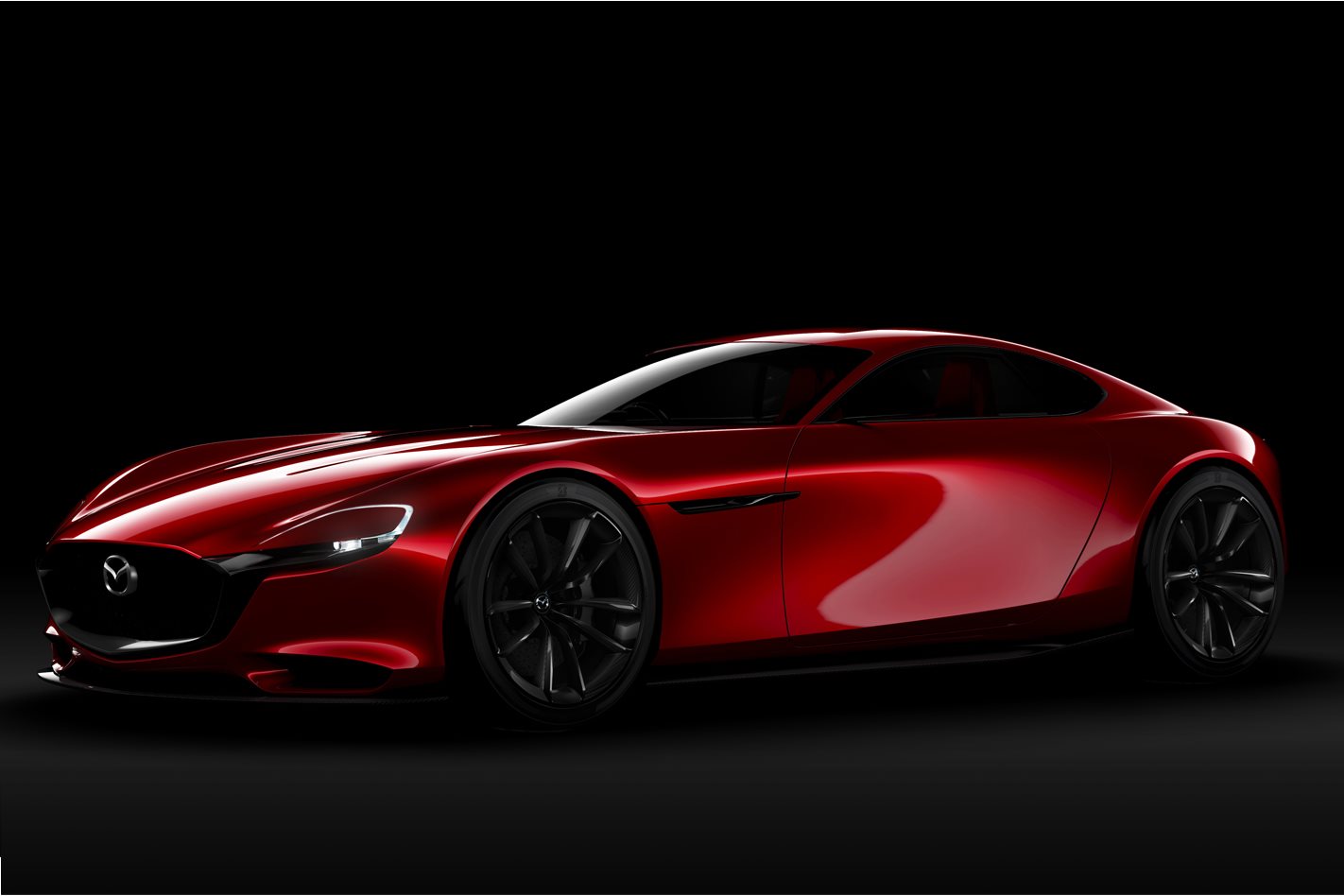

In a rotary engine, all of the main internal components spin in a largely circular motion, so it’s a simpler, more efficient transfer of energy from burning the petrol to turning the wheels. As such, the rotary has fewer moving parts, is smaller, lighter and more powerful for its capacity.

While Mazda is without doubt the rotary’s champion, the Japanese brand is not the only manufacturer to have dabbled in the idea.

Also like conventional piston engines, the rotary engine’s rotor layout can be duplicated for a larger capacity and more power. Most rotary models were ‘twin’ rotor, but Mazda has created three and four rotor versions.

However, as you might expect, this brilliant idea has disadvantages.

Sealed fate

Firstly, the special seals (you might hear them called face, lobe-tip or apex seals) that help create the compression required for combustion are prone to wear. When this happens, rotary engines start to loose power and can burn oil too. Replacing the seals is a big job.

Emissions and economy

While the power characteristics of a rotary engine are very good, they are not so good when it comes to fuel economy and the impact on emissions is negative too. Turbocharging and catalytic converters in late designs helped to a degree, but not enough to preserve the principle with today’s strict regulations.

Power absolute

While the free revving nature of a rotary engine makes cars powered by them engaging and fun, it comes at a cost to low-end power and especially torque. This unique performance delivery limits the engine to specific applications and mostly sports cars.

Many car-makers have fiddled with rotaries, but only Mazda has gone into large-scale manufacture of them. And when it did in the 1960s and 70s, the poor reliability of the rotary all but bought the company to its knees. But modern technology and materials mean the rotary could have a future and if you’ve ever driven one, you’ll know how delightfully smooth and full of character they are.

Details are still very light and a model heralding the rebirth is yet to be announced but you may be able to cruise around under the power of this extraordinary power unit once again.

CUT COTS OF THE FLEET WITH OUR AUDIT PROGRAM

The audit is a key tool to know the overall status and provide the analysis, the assessment, the advice, the suggestions and the actions to take in order to cut costs and increase the efficiency and efficacy of the fleet. We propose the following fleet management audit.