Ever wonder what goes into the decisions behind which components come on your trailer?

For an OEM, it’s a complex evaluation that takes many factors into account. Mark Ehrlich, senior director of engineering for Wabash National, gave a Technology & Maintenance Council study group some insight into the decision-making process during a Sept. 17 session.

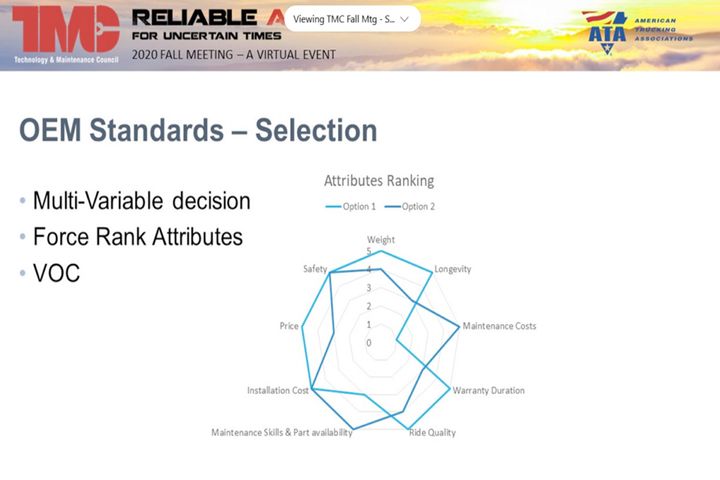

“The selection criteria is pretty intricate,” he said, referring to the evaluation of components such as suspensions, sliders, and wheel ends. “We are looking at multiple attributes in concert together to come up with the best result in terms of value.”

Those considerations include performance, safety, ride quality, weight, longevity, maintenance requirements, warranty duration, replacement part availability, and more. Data is heavily relied on by the trailer manufacturer to make those decisions.

Trailer makers also consider the complexity and cost of installation on their assembly lines.

In the case of a suspension, Ehrlich said Wabash considers the warranty and its construction. Is it corrosion-resistant? Are maintenance requirements reduced, for example, by using a mechanical fastener that doesn’t require torqueing? Are wearable parts readily available in the aftermarket?

For the slide rail, the OEM considers its longevity and examines the welds to ensure it won’t be prone to fatigue cracking. Ehrlich is wary of slide rails where welding has been done in high-stress areas.

For wheel-end components, Wabash wants to match up warranty with the life-cycle of the trailer. It wants to see long-lasting bearings and larger roller sizes. Lubrication requirements are also important, as are the wheel seals.

“They’re a very inexpensive part in comparison to the rest of the trailer but the wheel seal can cause a lot of cost later on if it fails,” Ehrlich noted.

Inner and outer bearings that are the same part number can simplify maintenance for end users.

Spring vs. Air Ride

Scott Bartlein, fleet manager for Barry Trucking, weighed the pros and cons of spring and air ride suspensions, noting it may be time to give spring ride suspensions a fresh look. If a fleet’s cargo damage claims are low, it may make sense to spec’ spring suspension trailers to save some cost.

Cargo packaging and load securement products have improved in recent years, Bartlein pointed out.

But on the other hand, air ride makes sense for cargo that’s fragile or lightweight, especially if it has come off a potentially rough sea journey.

Spring ride suspensions have the benefit of being lighter-weight, so payload can be increased. But then there are some customers who demand air ride suspensions be used to carry their freight. Will they pay extra for the benefit?

Spring suspensions are easier and two to four times less expensive to maintain, Bartlein noted. And if you’re pulling doubles, they’ll put less demand on your air system. Trailers with spring suspensions are also easier to examine during a pre- and post-trip inspections, which could help reduce roadside failures.

“I’m not bashing air ride,” Bartlein said. “I think there’s a need for them. All I’m saying is, as fleets we want to keep an open mind. One size doesn’t fit all and we need to take a fresh look at technologies.”

James Menzies is the editor of Today’s Trucking, where this article originally appeared. This content was used with permission from Newcom Media as part of a cooperative editorial agreement.

by James Menzies, Today’s Trucking

Source: https://www.truckinginfo.com

CUT COTS OF THE FLEET WITH OUR AUDIT PROGRAM

The audit is a key tool to know the overall status and provide the analysis, the assessment, the advice, the suggestions and the actions to take in order to cut costs and increase the efficiency and efficacy of the fleet. We propose the following fleet management audit.