A new electrically-assisted turbocharger “effectively eliminating” lag is coming soon to a production-vehicle engine.

In an announcement signaling automakers’ continuing R&D efforts for internal-combustion propulsion, Mercedes-AMG said it is preparing to launch a new, electrically-assisted turbocharger for engines to power its next vehicle generation. Confirming that the new turbocharger design will soon be fitted in a “series production” model line, the company said the electrically-augmented turbocharger delivers enhanced driving dynamics while also improving efficiency.

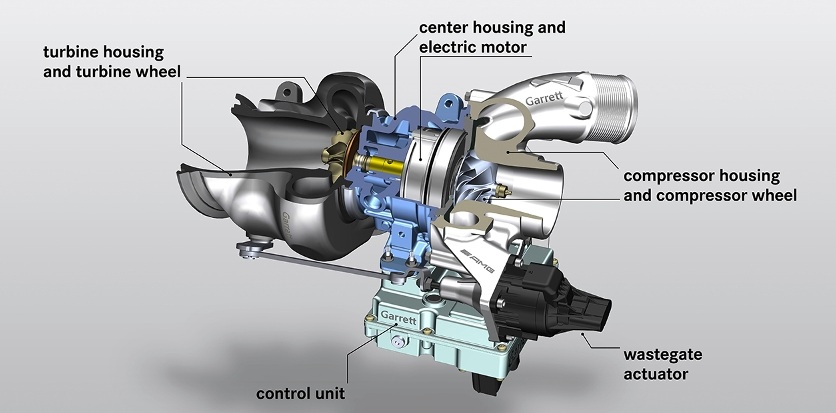

Mercedes-Benz and other automakers already have launched auxiliary electric compressors to augment conventional turbochargers, but this design integrates the strategy by using the electric machine to act directly on the shaft connecting the turbine and compressor wheels: the 1.6-inch (41-mm)-wide motor sits between the exhaust-driven turbine and the impeller that compresses the intake air directed into the engine. It can spin to a conventional turbocharger rate of up to 170,000 rpm.

The company said the electrically-assisted turbocharger, dubbed eTurbo, was developed in partnership with Garrett Motion and the technology “comes straight from Formula 1 [racing] and resolves the conflicting goals of a small, fast-reacting turbocharger, with relatively low peak performance, with a large turbocharger capable of high peak performance, while effectively eliminating the presence of turbo lag.”

The design is claimed to significantly improve response from idle, when there is low exhaust energy to drive a conventional turbocharger, and also is adept at retaining boost in engine low-load and transient situations such as coasting or braking that are prone to turbo lag when the driver again asks for acceleration.

48-volt companion

The eTurbo is accompanied by a 48-volt electrical system to provide the requisite power, although Mercedes-AMG did not detail the energy demands of the electric motor. The turbocharger and its integral electric machine as well as the accompanying power electronics are cooled by the engine’s thermal-management circuit.

“We have clearly defined our goals for an electrified future,” said Tobias Moers, chairman of the board of management of Mercedes-AMG GmbH in a release announcing the brand’s pending launch of its eTurbo. “In a first step, this includes the electrified turbocharger – an example of the transfer of Formula 1 technology to the road, something with which we will take turbocharged combustion engines to a previously unattainable level of agility,” he asserted.

Other turbocharger developers also are underway with similar technology. One, BMTS Technology (formerly Bosch Mahle Turbo Systems), detailed for media in mid-2019 an electrically-assisted turbocharger that it is targeting for early 2024 production. That unit, said Nisar Al-Hasan, BMTS director, growth & strategy, is designed to achieve a maximum speed of 216,000 rpm and requires approximately 2.2 kW of power.

The turbocharger also is designed to act as a generator to recuperate electricity and return it to the system’s battery when exhaust energy is in excess. Al-Hasan said BMTS’ cost target for the unit is less than $100 more than a conventional turbocharger.

Source: https://www.sae.org

CUT COTS OF THE FLEET WITH OUR AUDIT PROGRAM

The audit is a key tool to know the overall status and provide the analysis, the assessment, the advice, the suggestions and the actions to take in order to cut costs and increase the efficiency and efficacy of the fleet. We propose the following fleet management audit.