Consequences of Extended Truck Replacement Cycles

Extending truck replacement cycles beyond stated fleet policy is typically a short-term tactic by corporations to solve a budgetary constraint; however, there are long-term fleet consequences to this fiscal strategy.

Keeping trucks in fleet service for extended periods has been a long-standing and somewhat widespread phenomenon. The practice has even prompted a fleet management cliché that companies keep trucks in service until the wheels “fall off.” As with many clichés, this, in many cases, isn’t too far from the truth.

Typically, the more expensive the asset, the longer it will be kept in service, especially units upfitted with expensive auxiliary equipment. For example, service and utility fleets often have the highest capitalized costs, primarily due to upfitting, and tend to be those companies that keep their vehicles in service the longest.

Economic pressures, exerted by management, to realize short-term cost savings is the most common reason why truck replacements are deferred and cycling parameters are extended. For example, longer truck replacement cycles are more common for companies that self-fund vehicles, since deferring vehicle replacement is an easy way to stretch dollars when capital budgets are constrained. Similarly, in cyclical business segments, such as the construction industry, a number of companies look to cut costs during economic slowdowns by extending replacement cycles so cash flow can be diverted to other expenditures.

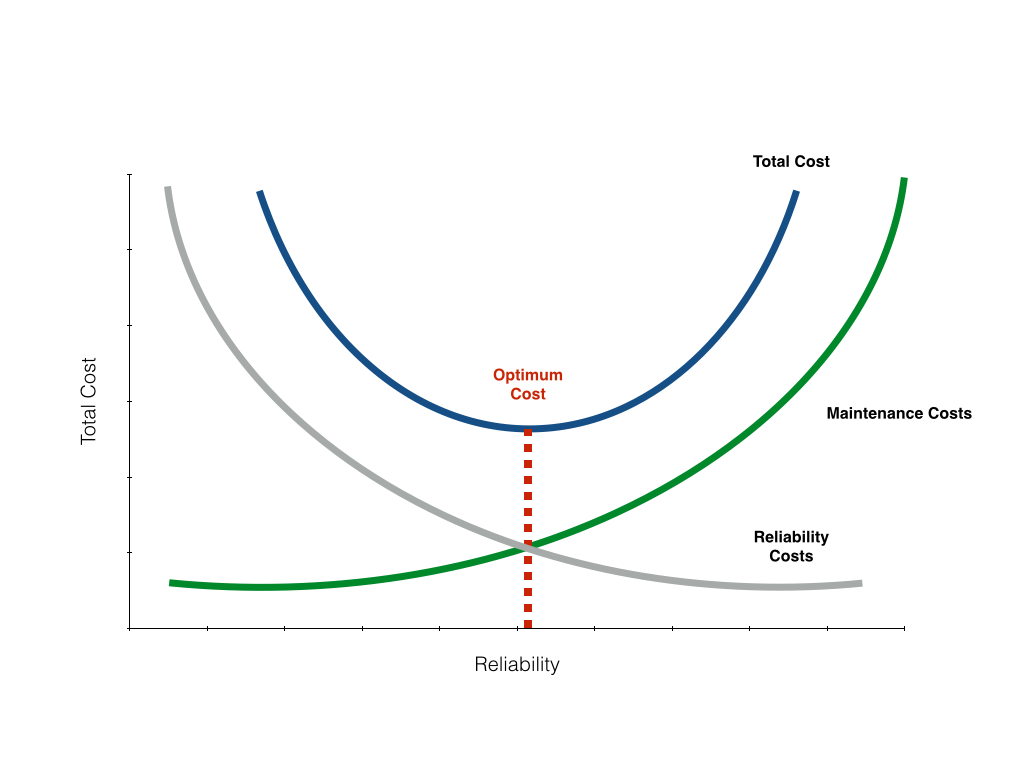

But, as study after study shows, extended truck replacement cycles for short-term capital expenditure savings often have the unintended consequence of resulting in greater long-term expenses, degradation in worker productivity, reduced resale values, and higher operating costs. In addition, long-in-the-tooth trucks typically need repairs that require longer turnaround times, resulting in longer driver downtime, and are more expensive to return to service. Another negative consequence to extending replacement cycles is the impact on budgets for future vehicle replacements. Each year a fleet manager does not replace vehicles, it will necessitate a greater expenditure in a future capital budget.

Calculating Overt and Hidden Costs in Extended Cycling

Industry data indicates truck fleets in many vocational segments have, on average, steadily extended the months in service for their light- and medium-duty assets. Admittedly, dramatic improvements in truck quality have allowed this to occur, but, ultimately, components will fail or wear out. Without a scheduled truck cycling policy, catastrophic component failures are more prone to happen, which are invariably unbudgeted costs. In addition, the unpredictability of component failure results in increased downtime, manifested in lost driver productivity, which Murphy’s Law ensures will occur at the worst possible time.

Budgeting for maintenance not under warranty is unpredictable, especially if a company does not rigorously follow scheduled preventive maintenance intervals. An increase in downtime results in lost business from missed jobs or missed opportunities to make a sales call. Critical component failures, which tend to occur more often with older assets, result in higher downtime costs per incident due to the complexity of the repair and longer turnaround time. Maintenance costs also increase because the additional months in service often necessitates an extra set of replacement tires and additional PMs.

Opinions vary as to the degree of financial impact of extended cycling, but there is one certainty, which no one disputes — maintenance expenses will go up. If they didn’t, the OEMs would not limit new-vehicle warranties by years and miles. The unknown is how much maintenance costs will rise as replacements are deferred. The magnitude of these additional maintenance costs to service aging assets is directly influenced by a company’s preventive maintenance program during the service life of the truck.

The biggest risk is not accommodating for increased maintenance costs due to having more preventive maintenance than originally anticipated and/or the truck encountering more frequent repairs. It’s not the cost of the repair so much as it is the downtime of that truck, especially when there is no replacement or backup unit available because of budget constraints that are driving the extended replacement cycle in the first place. If budget constraints prompt replacement deferral, in some cases, older trucks can be substituted with long-term rentals, at least until the next year’s budget allows replacement. This short-term tactic can be insurance against possible downtime and potential major maintenance expenses that may occur at the end of a truck’s lifecycle.

If budget constraints prompt replacement deferral, in some cases, older trucks can be substituted with long-term rentals, at least until the next year’s budget allows replacement. This short-term tactic can be insurance against possible downtime and potential major maintenance expenses that may occur at the end of a truck’s lifecycle.

While a rental truck can function as a short-term bridge to next year’s budget and a form of insurance against unscheduled repair cost, it will still incur the additional expense of rental costs. Likewise, a rental truck may not be available in your local market that can perform the same work and specific task as that of that of the out-of-service truck.

An important soft cost to consider is the cost of downtime. Companies that rely on trucks to run their business will tell you it runs thousands of dollars per hour for one of their trucks being down for unexpected reasons. Basically, if you extend replacement cycles you need to plan for the unexpected repair.

When unexpected downtime occurs there are direct costs, such as lost revenue and penalties or fees on missed appointments, towing charges, temporary rentals, overtime, and also indirect costs such as lower employee morale that need to factor in your risk analysis.

Downtime directly correlates with maintenance, specifically, the hours involved with a vehicle and driver out of production due to maintenance occurrences. Critical repairs tend to see higher downtime costs per repair due to the complexity of the repair, and the time required to complete is longer than more routine repairs.

Since depreciation is a truck fleet’s largest expense, many fleet managers believe extending the replacement cycle by a short period of time can lower a fleet’s fixed costs. This is true, but if the extension is for a longer-term, such as more than six months, uncertainty in resale values, unscheduled maintenance, and resulting downtime can more than offset any depreciation savings.

Sometimes, a company will spend more money repairing a vehicle than it is worth. Essentially, they are substituting operating funds for capital expenditure funds. In some cases, fleets may have no choice if the capital budget is significantly constrained or reduced.

Another operating cost impacted by longer service lives is fuel consumption. As a truck ages, the performance of the vehicle deteriorates, degrading fuel economy. Industry research suggests older trucks can lower fuel economy by 1% or more per year. Similarly, a longer service life will impact resale value.

Remarketing efforts are more difficult for higher-mileage, tired trucks, which typically result in lower resale prices.

Impact on Vocational Fleets

Budgeting for vehicle replacements can be challenging in a strong financial climate, and downright complicated in a difficult economy. To keep the fleet within a manageable age, a consistent replacement budget must be continually maintained. The stakes are even higher for vocational fleets requiring reliable vehicles capable of handling highly specific jobs — where downtime results in the lost productivity of a revenue generator.

As budgets for replacement vocational vehicles are cut, any capital savings achieved is generally shifted to the expense column of the operating budget. This is due to the increased total cost of ownership for an aging fleet. The following points highlight the greatest areas of concern:

Maintenance. Preventive maintenance is critical for vocational vehicles. As vehicles age, maintenance costs can increase significantly. In the case of upfit vehicles, these costs include the maintenance of ancillary equipment as well.

There are few benefits to extending replacement cycles unless an organization makes moderate adjustments to policy and manages the program very tightly. Small shifts in policy may be acceptable; preventive maintenance expenditures may not increase and the probability of catastrophic failure is not significantly increased. However, it is critical to establish and adhere to a policy that avoids additional sets of tires and brakes.

Thus, if cycling parameters are extended to slightly below the next tire/brake/preventive maintenance interval, increased maintenance expense may be minimized and overall cost of ownership may be reduced. When fleets extend replacement cycles, consideration should be given to the impact on residual resale values; the potential costs and impacts of vehicle downtime and loss of productivity; the increased probability of safety-related issues; the impact deteriorated vehicles have on company image and driver morale; and the degradation of fuel economy. It is also significant to recognize if replacement order delivery is slow, the potential savings previously gained on paper may be mitigated by unforeseen circumstances and may not be recovered in the resale of the vehicles.

As vehicles age, more expensive and potentially catastrophic repairs will occur. Without proper routine maintenance, the timing of the unscheduled repairs becomes even more unpredictable.

In short, budgeting for maintenance not under warranty is unpredictable, especially if routine preventive maintenance does not follow recommendations. If the ultimate decision is to extend vehicle cycling, implementing a fleet maintenance management program is recommended to handle the repair negotiations and post-warranty recovery.

Fuel efficiency and expense. Fuel costs are a major factor in the bottom line of any fleet management program. Although the initial capital outlay may be higher for newer, more fuel-efficient vehicles, the fuel cost savings realized over the vehicle lifecycle, for most lighter-duty assets, can outweigh the initial acquisition costs. Therefore, postponing the vehicle cycling process can sacrifice considerable savings available through more efficient engines and the newest technology.

Emissions and idling. In California and many other regions of the country, diesel vehicles and equipment are subject to strict emission-reduction regulations. New diesel vehicles meet current emissions regulations. Attempting to remain compliant through retrofits, relocations, and other temporary solutions could ultimately be more costly than the purchase of new vehicles.

Downtime and lost productivity. Any vocational vehicle downtime due to unplanned engine or equipment repairs results in lost productivity of a revenue generator. Without its working “tools,” the disrupted vocational fleet jeopardizes a company’s ability to effectively serve its customers and generate revenue. As mentioned earlier, short-term heavy-duty truck rentals are costly and rarely match the specific capabilities of a company-owned vehicle.

Alternative funding. For medium-and heavy-duty leased vehicles, an option could be a residual-style lease re-amortized upon lease termination. This effectively creates a much longer funding period. For example, a 60-month lease with a 50% residual will perform like a 120-month lease schedule. Once the original lease term has expired, the remaining residual can be capitalized into a second 60-month lease with a 0% residual. This allows fleet managers to match the expected lifecycle of longer-duty vehicles with an affordable funding cycle.

Impact on Acquisition Budget

Budgeting for vehicle acquisitions varies according to whether fleet vehicles are leased or owned.

Under ownership, most companies must establish a capital budget for acquiring assets. The capital budget is for the total acquisition cost of the vehicles planned for replacement. Thus, a critical step in preparing the budget is accurately forecasting the number of vehicles requiring replacement. Once the budget is in place, acquisitions are made using a capital expense authorization request. Because of the nature of the budgeting process under ownership, oftentimes vehicle acquisitions are made at a less-than-optimal time of year, for fear of losing the capital budget later that year.

In companies that own vehicles, deferring replacement to save money on the capital budget is easy. For that reason, oftentimes poor replacement practices are seen in which short-term capital expenditure savings are sacrificed for longer-term expenses and productivity impacts. The net result can be a very old fleet with a high incidence of spare vehicles, as spares accrued are no longer depreciated on the books.

There are many examples of companies that own their vehicles and have educated their business planners on the needs of fleet and best practices that allow fleet performance optimization. They have convinced their management of the need for regular replacements, total cost of ownership (TCO) management, the impact of driver productivity, optimal fleet sizing, etc.

Acquisition budgeting for leased vehicles is a bit easier. Generally speaking, one lease payment is traded for another, plus or minus residual gains and losses, and any impacts from new-vehicle price changes. In the leasing example, the critical factor becomes optimizing the TCO. Here, all the cost factors, such as depreciation, maintenance, fuel, driver downtime, etc., are all accounted for in the replacement decision.

Three Other Considerations

Other arguments against extended replacement cycling include:

1. Employee morale: A good rule of thumb is that the older vehicle, the more the problems. As the frequency of repairs increases, many employees perceive the vehicle as more a nuisance and do not care for the vehicle’s internal and external condition the same as they would a newer model. The direct result is a diminished resale value due to below-average condition status.

Not only is the service of the truck affected, but it also affects the operator. If employees aren’t feeling good about the equipment they’re using, or if the vehicle is unreliable, that is going to start to have a negative effect on productivity and morale, which may mean drivers will let their guard down in caring for their vehicles. This, in turn, creates a snowball effect, which can drive up repair costs.

2. Company image: Body damage, rust, peeling decals, and breakdowns on the road occur with greater frequency with older vehicles. The condition of a company’s vehicle may be the first impression a customer or prospect may get is when they see the vehicle. If a company markets itself as a high-quality repair business and the service van shows up with body damage and rust, the customer may relate the presentation of the vehicle to an implied lower quality of repair.

3. Unbalanced cash flows from irregular ordering: Extending cycling based on current cash flow requirements upsets future cash flow budgeting for subsequent years. In short, it is difficult to get back on track once the budget has been disrupted, as budgets are typically set based on prior years’ expenses. In addition, if the economy worsened the following year, the problem would be exacerbated to the point the fleet manager may defer the second-year cycle. Thus, in the third year of the cycle, a much larger number of vehicles would need to be ordered at higher capitalized costs.

Low-Cost Ways to Extend Replacement Cycles

There are several ways to extend replacement cycles without the long-term negative consequences.

Route Optimization: The vehicle replacement cycle is typically driven by mileage and/or engine hours. So if you can lower miles/engine hours by optimizing the routes that will help with extending the life of the vehicle.

Engine Idling Management: Managing idle time will minimize unnecessary engine hours. A telematics tool can help with managing engine idle time and route optimization to extend the service lives of your vehicles.

Low-Utilization Vehicles: Before replacing a unit, a few fundamental questions must be asked: Is the vehicle being fully used? Vehicle’s utilization should be evaluated and taken into account to determine whether to replace the unit at all. If the vehicle has consumed fewer than 500 gallons of fuel or been used less than 2,500 miles during the past 12 months, it should be evaluated whether it still is needed.

Vehicle Reassignment: One effective way to extend service life is to shift the vehicle assignment, such as moving high-mileage trucks to a lower-mileage application.

by Mike Antich

Source: https://www.worktruckonline.com

Source:  I´m a Fleet Management expert, and the manager of Advanced Fleet Management Consulting, that provides Fleet Management Consultancy Services.

I´m a Fleet Management expert, and the manager of Advanced Fleet Management Consulting, that provides Fleet Management Consultancy Services.