Over the past 30 years, the logistics industry is concerned not only in their financial bottom line, but also in the environmental footprint of their operations and supply chain management, especially in terms of the costs and strains of energy consumption and carbon emissions. Addressing this issue not only protects the environment and reduces your company’s carbon footprint, but it saves money and improves efficiency.

The question is, how do we put this into practice?

Price Waterhouse Coopers (PwC) has engaged not only in financial auditing but verifies the carbon footprint verification for more than 300 companies across Europe. Volume one of their Transportation & Logistics 2030 report focused on ”How will supply chains evolve in an energy-constrained, low-carbon world?”

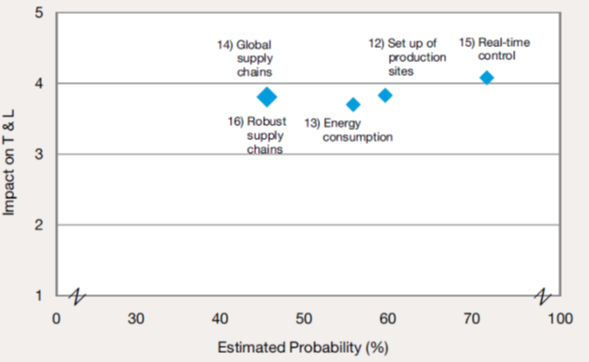

Their experts believe that supply chains will continue to become more efficient through the development of continuous real-time control of the flow of goods, as this trend receives their highest overall probability and desirability ratings from survey respondents.

Source: Delphi results of design of future supply chains. Transportation & Logistics 2030. Volume 1: How will supply chains evolve in an energy constrained, low-carbon world? ©2009 PricewaterhouseCoopers.

Most companies look to reduce energy consumption and their related costs. In turn, the logistics business and their service providers will need to balance energy efficiency together, with greater speed to support supply chains which take into account both factors. Therefore, the experts assert that a key factor behind control and efficiency is collaboration.

A driver to promote collaboration is an increased connectivity. The CDP Supply Chain Report for 2014 -2015 shows that as a result of their connectivity, digital supply networks deliver visibility and traceability, and facilitates collaboration in the different steps of the supply network. This connected partnership empowers suppliers who are connected, in order to exchange information and create awareness about sustainable practices, share knowledge and develop solutions.

Technology will help enable greater flexibility in operating models, as future digital supply networks will allow manufacturers to align operating models to their sustainability goals in terms of resource and energy efficiency. A digital supply chain with synchronized and integrated partnerships are key to improve environmental and financial savings.

An example is Procter and Gamble (P&G). In an article written for The Guardian, P&G states that since 2002 they have halved the impact on the environment in terms of energy usage, CO2 emissions, waste disposal and water usage. In turn, they have has saved nearly $1 billion.

In 2007, they set a target to reduce road kilometers traveled by trucks by 30% by 2015. The company has already achieved this throughout Western Europe by using intermodal transport, redesigning their networks and establishing “green corridors” between their major logistics locations. For retailers that partner with them, the partnership means faster, smoother, more efficient and less cost-intensive operations.

What are your company’s concerns regarding its environmental impact? How have you worked to address them? I would love to hear your feedback. Leave me a comment below.